No one wants to see a damaged package and product when they receive a courier. Developing a harmonized and structurally winning packaging is not a stroke of luck. It takes research, planning, multiple transit trials and a strong execution foot to build sustainable packaging inventory and SOP(standard operating process) at the warehouse. The reason so much effort and planning is invested in developing packaging is so that there is less chance of packaging damages at operations and transit ends.

But how can you tell if your packaging is the culprit of your poor product performance? To diagnose the correct reason for failure is another research-heavy activity as there can be multiple scenarios:

Product(damage) + Packaging( not damage)= Fail

Product( not damage) + Packaging(damage)= Fail

Product(damage) + Packaging( damage)= Fail

Here are six general guidelines to follow while developing your packaging and missing multiple such approaches could be the reason for product & packaging damage.

Optimized Dimensions

Many times we have received a courier with a huge carton for one small product. Definitely, we feel what a waste of material! It’s not just a waste of material, we are providing space for the product to rattle which will cause damages to the product and due to internal pressure, it will also cause damages in the main carton. Optimised dimensions help in restricting the product laterally, vertically and rotationally movement.

Assembling & Bundling

The stacking of multiple SKUs needs good planning. Layouting the stack according to the nature of multiple product’s weight, dimensions, shape and their primary packaging material. So, that every product is safe in transit. The process is similar to when we go grocery shopping, where we purchase both perishable and non-perishable items. While shopping we keep the rigid and heavy products in bottoms like oil cans, segregate delicate items like fruits into a different polybag, club similar weight and density products together like french beans and cluster beans and keep liquid items arrested vertically on one side. Similarly, the rules apply to the warehouse operations team and require training of ground-level staff so that they can prepare the layout efficiently.

Specification Optimization

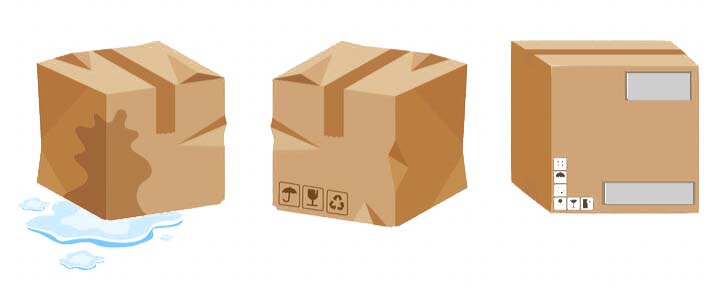

What is material specification?

Specific and detailed information regarding the chemical and structural composition. For example, let’s take a corrugated box. Corrugated box strength is determined by 4 major factors- thickness and flutes, Bursting strength, Edge crush strength and water absorption rate.

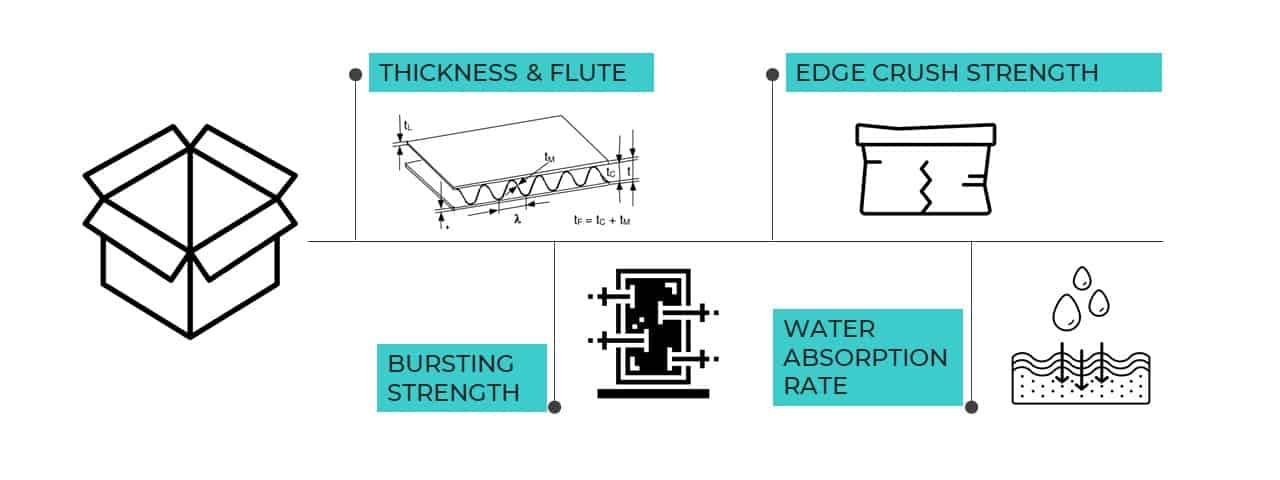

Why is it important?

Specification of material can play a pivotal role in the cause of damage. Many a time brands used recycled corrugated sheets that have already gone through wear and tear and impact product during transit. Providing higher specs is not feasible cost-wise and is also not sustainable in the longer run. We need to understand three factors: Product, environment and packaging to achieve a balanced solution.

Selection of Materials

Mostly it takes more than one material to protect a product. We need to scientifically choose the amalgamation of materials for a product. A common mistake most brands do is rely on one material for cushioning and compression strength. For eg: Majority of brands on e-commerce platforms heavily rely on bubble wrap to protect the product. It is not economical or effective. Bubble wrap just provides cushioning but we also need compression members to keep the packaging intact.

Intactness

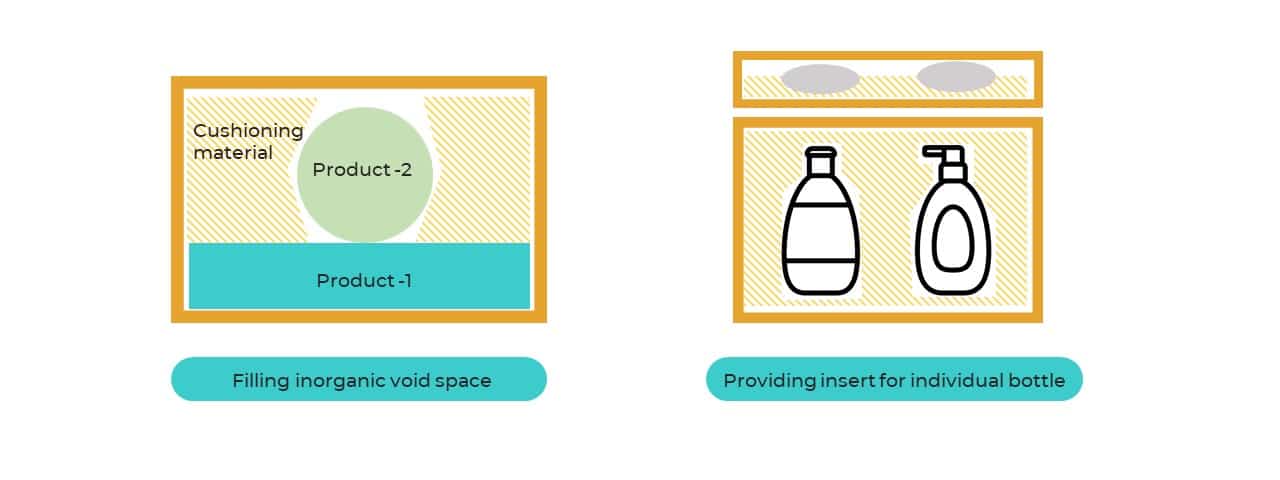

Intactness is keeping the product stable at one position and restricting any movements inside the packaging. Just providing cushion to product sometimes does not suffice, it is also required to be intact at one position to avoid rattling. There can be two ways to achieve it:

- Filling void spaces: There can be geometric and organic void spaces, so choosing appropriate material here becomes very crucial.

- Placing insert with a pocket so that a product has a dedicated space

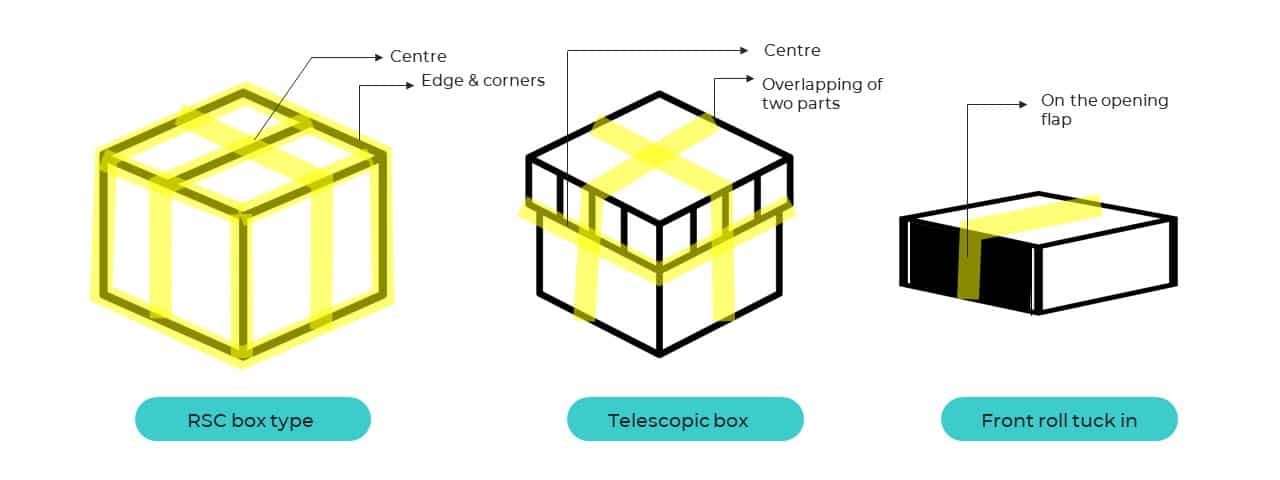

Securing

Last and foremost, securing the packaging. The most common material used for securing the packaging is BOPP tape. How much tape to put on the package? Generally, we see the entire package filled with BOPP tape and it is one of the most tedious tasks to remove the tape from packaging. We need to understand the focus areas and where the tape is more effective. Especially, when we start moving towards heavy goods, securing the packaging becomes very critical as it needs to pass a lot of tests.

Developing a hassle-free packaging and securing product for transit involves scientific calculation, research and planning execution.

I hope this article helps you as a checklist while developing packaging and reduce the chances of failure.

If you are facing a similar issue and want to discuss out in detail, you can reach out to me at amitajain16@gmail.com

I'm an Industrial Designer with a specialization in Structural Packaging Design and Research.

Over the past 9 years, I have had the opportunity to work with multiple renowned brands, startups and have also collaborated with independent brands to conceptualize, mentor and implement innovative design strategies for their packaging.

As I am venturing into the packaging subject deeper and interacting with multiple stakeholders from concept to execution, I am learning to work on simple approaches and devising tools based on logical thinking which can make the design process enriching.