Mushroom packaging? With increasing concern over the use of plastic and its negative consequences, a completely natural packaging material may be an innovative replacement.

Learn more about mushroom-based packaging made from mycelium in a comprehensive case study

With increasing concern over the use of plastic and its negative impacts on our health and our environment, a completely natural packaging solution may be an innovative replacement to reduce our dependence on fossil-fuel based materials. Mushroom based packaging made from mycelium is a promising renewable alternative that offers many benefits compared to plastic.

What Is Mycelium And How Can It Be Used In Packaging?

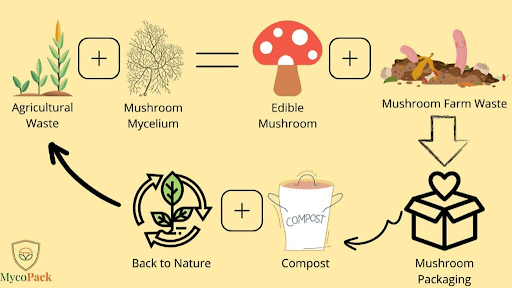

Mycelium is the living root structure of mushroom fungi. This root system contains a group of fibers that grow rapidly and act like a glue around the desired substrate. The mycelium growing process starts with feeding the fungi different forms of waste including agricultural waste from sources like hemp, hurd, or corn husks. Over a period of a few days the fibers of the mycelium spread like glue throughout the medium and grow in the form of any molded shape. Once the desired shape and weight of the mycelium packaging has been achieved, it is heated, stopping the growth process.

This process has been patented by Ecovative, a New York based company, to produce various mycelium products, including packaging. According to the Mushroom Packaging website created by Ecovative, this mycelium packaging is home compostable, chemical free, and even water resistant, which makes it a good alternative for some plastics.

Mycelium Vs. Polystyrene

One promising use for mycelium based packaging is replacing the use of polystyrene, also known as Styrofoam. Polystyrene is a large contributor to litter and debris, which have increasingly found their way into our oceans. A large problem with polystyrene is that it is neither biodegradable or compostable and most facilities do not accept it for recycling. This means that polystyrene will sit in landfills for an estimated 500 years, along with polluting our oceans and creating risks for aquatic life. The production of polystyrene also uses high levels of energy and emits a significant amount of greenhouse gas emissions (GHGs).

The mycelium alternative, however, is compostable and biodegradable. It can break down within weeks of putting it in your backyard. Due to the natural makeup of the packaging as it decomposes, it provides the soil with nutrients and acts as fertilizer. The production process of mushroom packaging starts with the mushroom’s growth, which absorbs carbon dioxide during the process and may make its carbon footprint comparatively better than polystyrene.

Who Is Using This Mushroom Packaging?

Some large companies like Dell have incorporated mushroom based packaging for their products. Beginning in 2011, Dell began to use the natural fungi for cushion packaging used in shipping their servers. After extensive testing, Dell has found that this alternative is suitable for shipping some of their heavier products, like servers. The mushroom cushions take 5-10 days to grow and all required energy is in the carbohydrates of the mushrooms, meaning no added fuels are necessary. In order to ensure consumers are properly disposing of the compostable mycelium packaging, the Recycle and Compost Your Packaging web page provided on Dell’s website gives directions not only on how to dispose of the cushion but also other packaging components. Dell has been committed since 2009 to use more environmentally friendly packaging materials like bamboo and mycelium, leading the way for mainstreaming sustainable packaging in large companies.

There has also been discussion that other companies such as IKEA will begin using mycelium based packaging alternatives to help their company reach their sustainability goals. IKEA is currently trying to phase out all plastic consumer packaging by 2028, and alternatives like mushroom packaging could be a viable solution in achieving this goal.

Pros And Cons Of Using Fungi To Replace Polystyrene

The widespread availability of agricultural waste across the globe is one advantage of mushroom packaging. Due to the abundance and variety of agricultural waste that can be paired with mycelium to produce packaging, it has the potential to be relatively accessible throughout the world. Another advantage is the low cost of raw materials which could also help accessibility.

According to the World Economic Forum, one disadvantage of fungi packaging is its short lifespan compared to plastic. Since the material will decompose after just a few short weeks it is not ideal for companies working and or shipping long distances. Another concern is its durability when compared to plastics like polystyrene. The lack of durability makes it less favored for uses such as holding prepared food. Additionally, mushroom packaging is not currently as versatile or widely available as plastics, which still makes plastic the better option in some categories.

Conclusion

Innovative packaging specialists across the world are racing to find suitable alternatives to reduce our dependence on plastic. Mycelium derived packaging may turn out to be a useful addition to sustainable solutions. In order to quantify and support the environmental claims surrounding mycelium packaging and other cutting-edge innovations, it would be beneficial to complete a Life Cycle Assessment (LCA). Comparing mycelium based packaging with polystyrene would greatly help consumers and packaging specialists alike to understand the real difference in environmental impacts. Here at Trayak, we provide EcoImpact COMPASS, a comprehensive sustainability software solution tailored to products and packaging. It aids in easily making comparisons between packaging alternatives, determining hotspots, and weighing environmental tradeoffs to reduce your overall impact. EcoImpact COMPASS is data-driven and uses regionalized data to consider end-of-life scenarios like recycling, composting, landfill, and waste to energy.

Original Source: www.trayak.com

Trayak’s Vision is that all companies will design and manufacture their entire portfolio using sustainable strategies.Trayak allows you to bring real innovation to product sustainability throughout your product life cycle — design, engineering and manufacturing.