Simple, practical and good for the environment. This is how the latest innovation from ALPLA can be described. The lightweight mono-material tube is fully recyclable, suitable for use as a refill pack and convenient for consumers to use. But the real highlight is the clasp.

In June 2019, the European Union declared war on pollution of the oceans with a new directive. In addition to the ban on various disposable plastic products (e.g. straws or cotton buds), the legal text also contains new specifications for closures for beverage bottles. From 2024, these must remain attached to bottles or composite packaging under three liters during drinking and also after use. ALPLA already presented concrete solutions for the so-called tethered caps at the beginning of 2020 .

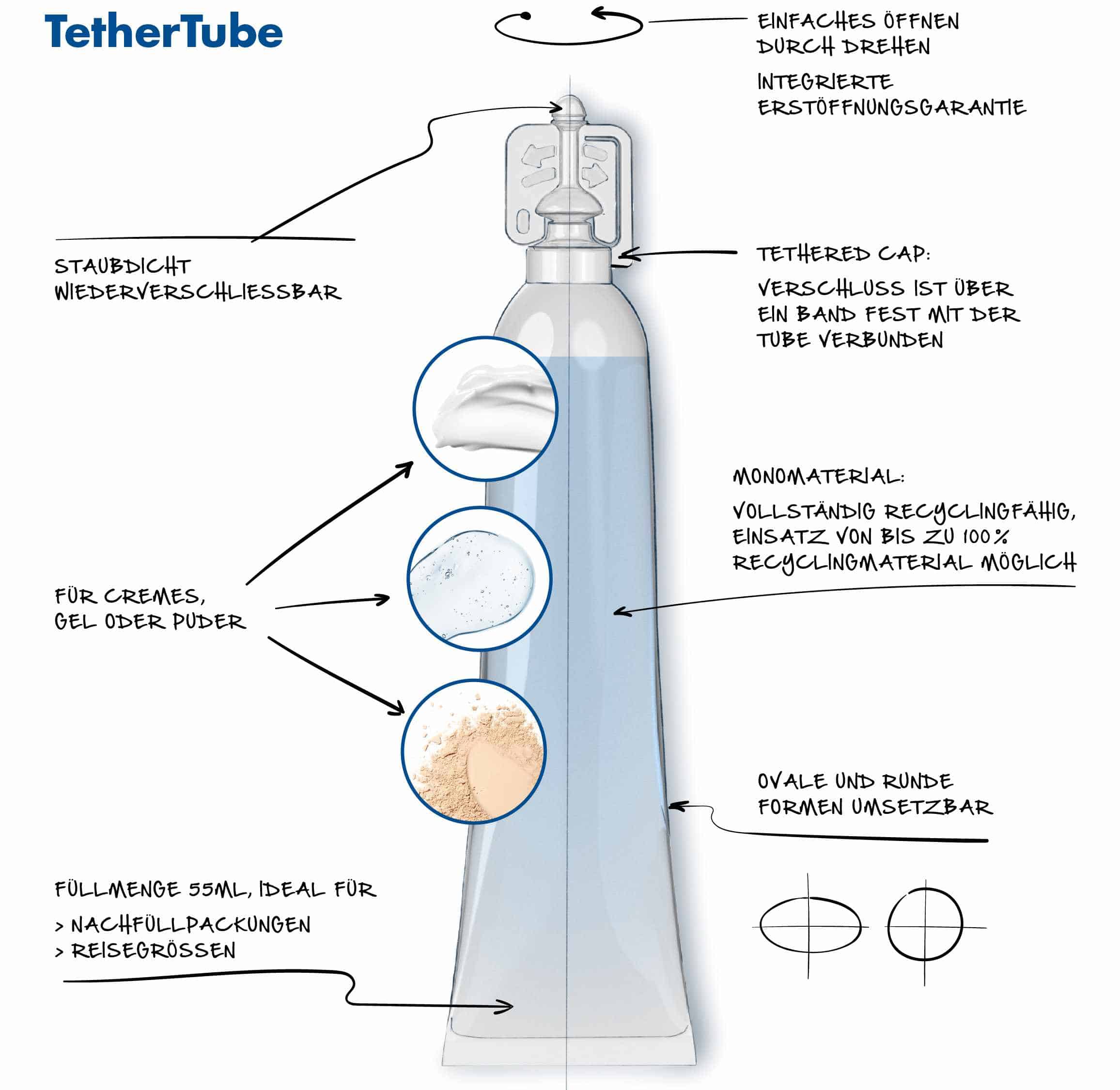

With Tether Tube, ALPLA thinks one step ahead and also implements these specifications for tubes. The closure with integrated tamper evidence is firmly attached to the tube body. When the tube is opened, there are no loose individual parts such as sealing foils or closures.

A single piece

Manufacturing tubes is not quite as easy as they are to use. They consist of a tube body, shoulder and cap and are often equipped with a sealing foil for better product protection. Tether Tube, on the other hand, consists of one piece, i.e. it is made of one material in a single production step. Completion steps in the manufacturing process are completely eliminated. The finished tube is delivered to the customer with an open end, where it is filled and sealed.

Before the first opening, the Tether Tube is tightly closed. The closure can be opened at a defined tear-off edge without any effort. Nevertheless, the tube withstands a fall from a height of two meters directly onto the closure without leaking at the tear-off edge. Handling is intuitive, arrows on the top of the tube guide the consumer. These arrows also increase the rigidity of the closure and thus simplify handling. The band is long enough, the cap can be bent backwards and is therefore not a hindrance when emptying the contents. If not all of the content is needed, the tube can be closed dust-tight with the top tip of the cap. To do this, the plug is inserted into the opening until it audibly and noticeably clicks into place.

In addition to the obvious advantage of the firmly attached cap, this tube offers numerous other advantages:

- Weight: Tether Tube for a capacity of 50 milliliters weighs only 6 grams.

- Choice of material: Tube and cap are made of just one material. Depending on the area of application and the viscosity of the filling goods, HDPE or LDPE can be used. The use of up to 100 percent recycled material is possible.

- Recyclability: The tube is made entirely of recyclable polyethylene (HDPE or LDPE) and is optimized for recycling. In the sense of an efficient circular economy, new tubes can be produced from tubes (no downcycling).

- Convenience: Handling is simple and intuitive, the tube can be opened without any effort. The attached breech eliminates the possibility of accidentally dropping the breech and searching for it. The closure does not have to be held during use, handling is not impeded thanks to the long tether strap.

- Areas of application: Tether Tube is suitable for liquid and powdery filling goods, so the range of applications is very wide. The design can be adapted to the respective filling, for example in terms of material selection or resealability.

- Refill and e-commerce: This handy packaging solution is also ideal for refill packs (e.g. concentrates for household cleaning agents). The outer packaging can be optimized for the requirements of online shipping. The consumer does not even have to be at home to receive the package, as the packaging fits in a standard mailbox.

PROJECT MANAGER FOR INNOVATION

Florian studied industrial engineering with a focus on innovation and systems engineering in Weingarten, Germany. The 26-year-old gained his first professional experience at a start-up in the bicycle industry and in the field of pharmaceutical packaging. He has been project manager for innovation at ALPLA since January 2020 and is particularly dedicated to the search field frugal packaging.