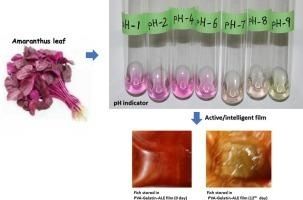

Scientists at the Bhabha Atomic Research Centre, Food Technology Division, in Mumbai, India have developed a composite active food packaging film with polyvinyl alcohol (PVA) and gelatin incorporated with Amaranthus leaf extract (ALE) to monitor freshness of raw fish and chicken meat.

ALE showed excellent antioxidant activity and changed colour under basic pH due to betalains being present in it. Film containing ALE showed increased protection against UV light, reduced water solubility and water vapour permeability and had better mechanical properties. Additionally it imparted antioxidant, antibacterial and intelligent properties to the film. When applied to preserve chilled fish and chicken, the films delayed microbial growth and minimised oxidative rancidity.

Samples packed in untreated films had a shelf life of 3 days, while those in the active films spoiled after 12 days. The film also showed visible colour change from red to yellow on spoilage and this corroborated with the increase in pH, total volatile basic nitrogen (TVBN) and microbial counts of the spoiled samples.

Next a team of researchers, based at Guangxi University and Nanjing Forestry University in China, have developed a sugarcane bagasse nanocellulose-based hydrogel which can be used as a colourimetric freshness indicator for monitoring spoilage of chicken meat.

Nanocellulose was prepared from sugarcane bagasse cellulose filaments by TEMPO-mediated oxidation, and then used to form a strong self-standing hydrogel matrix. The hydrogel worked as a carrier for pH-responsive dyes, which changed colour, from green to red, according to the freshness of the chicken sample. Carbon dioxide levels were found to increase with the spoilage of chicken, relative to rising levels of micro-organisms. The quick response to chicken spoilage is expected to facilitate its utilisation as a value-added material in intelligent packaging.

Finally a team at Jiangsu University in China and Leeds University in the UK has developed a hydrophobic using low density polyethylene (LDPE) and curcumin. The hydrophobic nature of the LDPE endowed the film with good stability to pH buffer solutions.

When the LDPE-curcumin film was used to monitor beef and silver carp spoilage at 4 °C it showed light yellow-to-light brown colour changes over time, resulting from the increasing TVBN content of the meat samples. The team says the tested film is totally non-toxic and suitable for industrial production in at large scale, so has good potential for applications in intelligent food packaging.

All these reports appeared in Industry Intelligence during November.

Source: AIPIA Newsroom

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.