Plastic packaging waste may comprise residues fromearlier use, impurities from misuse andcontaminants from non-authorised substances.Therefore, it is necessary to lay down special requirementsto ensure that materials and articles produced fromrecycled plastics and intended for food contact with respectto the Indian national and international regulatory compliance requirements.

In January this year, the Food Safety and Standards Authority of India (FSSAI) has issued a directiontowardspermitting the use of recycled plastics as food packaging materials by amending the Plastic Waste Management (PWM) Rules 2021 notified on September last year. However, as per the Plastic Waste Management Rules, 2016, the use of recycled plastic was prohibited for food contact applications.Now, as per this amendment, products made of recycled plastics including carry bags may be used for packaging, storing, carrying, or dispensing of food products as per the acceptance criteria provided in the said ammendmentwith special reference towards recycled Polyesters (r-PET).

Scope For Acceptance Criteria For R-PET

This is applicable for transforming Post-consumer PET into food-grade recycled PET and not related to industrially rejected PET bottles. This amended rule is irrelevant for non-food applications and covers acceptance criteria for food packaging application. The post-consumer PET needs to be sorted, cleaned, decontaminated as per US/EU or equivalent standard, and further transformed into food-grade recycled PET (FG r-PET).

Type Of Recycling Process And Approval Criteria

CONVENTIONAL MECHANICAL PROCESS: During this process the Post consumer PET flakes are mechanically recycled through washing, melting, extruding and pelletisation without a decontamination process. As it does not have the decontamination process step, it is not approved and considered by FSSAI for food packaging application.

HIGH HEAT – HIGH VACUUM PROCESS: There are mechanical recycling processes such as Super-Clean recycling process and Melt-in recycling process which involve high heat and high vacuum steps for decontaminating the r-PET, and thereby approved by FSSAI for FG-r-PET applications. For Super clean recycling process and Melt in recycling process, the level of decontamination shall be below the 220 µg/kg limit in the resin for each surrogate contaminant by an extraction test (per USFDA), or below the 10 µg/kg limit in the beverage or food simulant for each surrogate contaminant by a migration test (as per EU).

CHEMICAL RECYCLING PROCESS: There are two kind of chemical recycling process mentioned in the FSSAI document such as Paste-in Recycling Process involving partial glycolysis and chemical distillation process; another one is Enhanced Chemical Recycling Process equipped with a chemical reaction operation of pyrolysis or fully depolymerizing PET Flakes into purified ethylene glycol and terephthalic acid (or dimethyl terephthalate), or bis(2-hydroxyethylterephthalate). For both these Processes, Food Grade rPET shall be equivalent to virgin PET and meet the requirements of Food Safety & Standards (Packaging) Regulations, 2018.

Procedures On Submission Of A Dossier For Safety Evaluation By The EFSA

According to the Regulation (EC) No 282/2008 on recycled plastic materials and articles intended to come into contact with foods (European Commission, 2008), recycled plastics used to manufacture materials and articles intended for food contact shall be obtained only from processes authorized by the Commission following a safety assessment performed by the European Food Safety Authority (EFSA). The Regulation also states that the recycling process shall be managed by a quality assurance system (QAS) that has to meet the requirements laid down in the Annex of Regulation (EC) No 2023/2006 (European Commission, 2006).

According to this procedure, the industry submits applications to the competent authorities of Member States, which transmit the applications to EFSA for evaluation. According to Article 5 of Regulation (EC) No 282/2008 on recycled plastic materials intended to come into contact with foods, EFSA is required to carry out risk assessments on the risks originating from the migration of substances from recycled food contact plastic materials and articles into food and deliver a scientific opinion on the recycling process examined.

According to Article 4 of Regulation (EC) No 282/2008, EFSA will evaluate whether it has been demonstrated in a challenge test, or by other appropriate scientific evidence, that the recycling process followed by the particular industry is able to reduce the contamination of the plastic input to a concentration that does not pose a risk to human health. The poly(ethylene terephthalate) (PET) materials and articles used as input of the process as well as the conditions of use of the recycled PET are part of this evaluation.

Usually, the following kind of information has been submitted to EFSA by the industry for further evaluation and approval:

General information:

- general description,

- existing authorizations.

Specific information:

- recycling process,

- characterization of the input,

- determination of the decontamination efficiency of the recycling process,

- characterization of the recycled plastic,

- intended application in contact with food,

- compliance with the relevant provisions on food contact materials and articles,

- process analysis and evaluation,

- operating parameters.

EU Approved Recycling Process

These EU guidelines apply to processes using mechanical recycling, whereby the collected plastics are ground into small pieces and decontaminated before being processed to new food contact materials. Chemical recycling processes, whereby the plastic is completely depolymerized into monomers and starting substances which are then reused in a polymerisation reaction are not in the scope of the Regulation and are not covered by these guidelines. Processes where the mechanical recycling is the main part of the whole process are in the scope of these guidelines provided that the plastic is not subsequently depolymerized.

Example of a valid recycling process approved by EFSA

In the mechanical treatment, in which the plastic waste is ground into small pieces and cleaned, special care has to be taken to remove these contaminations. The recycling process must demonstrate that it can efficiently reduce potential contamination to a level that does not pose a risk to human health. The contaminants should only migrate in levels comparable to or well below levels demonstrated in the challenge tests of that recycling process or in other appropriate analytical test and should comply with the requirements of Article 3 of Regulation (EC) No 1935/2004. A safety assessment should verify that the recycling process fulfils these conditions.

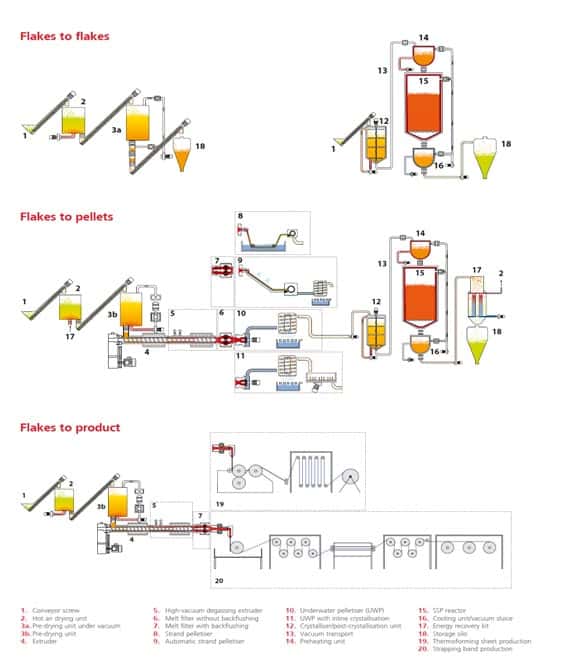

Starlinger IV+ Technology

The typical scheme of the StarlingerIV+ technology, as per available literature, is provided below. Here, PET flakes are decontaminated and IV-increased stand-alone or inline. In combination with the recycling extruder and pelletizing system the downstream vacuum SSP reactor ensures outstanding r-PET quality. Inline applications combine energy saving and value-adding in one step. Please go through Figure-1, for better understanding of this process.

The steps are:

In step 1, the post-consumer PET containers are processed into hot caustic washed and dried flakes. This step may be performed by a third party or by the applicant.

Decontamination and production of recycled PET material

In step 2, the flakes are dried and crystallized in a reactor at high temperature.

In step 3, the flakes are extruded at high temperature and then crystallized.

In step 4, the crystallised pellets are preheated before being treated in a solid-state polycondensation (SSP) reactor at high temperature. The operating conditions of the process have been provided to EFSA. Pellets, the final product of the process, are checked against technical requirements, such as intrinsic viscosity and colour.

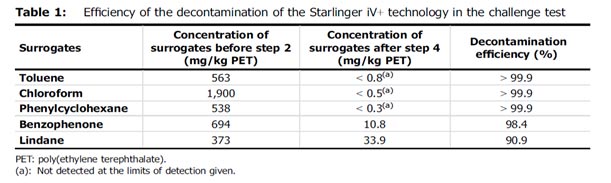

Challenge Test – a validation test in which recycled PET is exposed to a mixture of surrogate chemicals of different molecular weight and polarity at exaggerated levels, processed through the entire recycling process, and analysed quantitatively for the residual concentrations. Challenge test needs to be repeated in case of changes in process, process parameters or input feed. One such example of the challenge test has been provide below in Table-1 for reference. The decontamination efficiency of the process was calculated from the concentrations of the surrogates measured in the washed contaminated flakes before drying and crystallisation (before step 2) and after SSP (step 4). The exemplary results are summarised in Table 1:

Process Validation As Per FSSAIGuidelines

In line with EU guidelines and as validated by FSSAI, the recycling process shall have at least one decontamination step capable of removing contaminants to a level of purity suitable for food contact. The decontamination capability shall be confirmed with a challenge test. Investigational data of the challenge test shall be examined by a established competent authority. Only recycling processes that have been affirmed to be effective shall be regarded as Super-Clean. The level of decontamination shall be below the 220 µg/kg limit in the resin for each surrogate contaminant by an extraction test(in a USFDA challenge test – Refer Appendix), or below the 10 µg/kg limit in the beverage or food simulant for each surrogate contaminant by a migration test (in an EU challenge test). This needs to be validated with local raw material (PET feedstock).

Critical Analysis Of This Amendment on PWM Rules 2021:

Post-consumer materials – PET bottles are particularly mentioned in the draft, but other materials are not defined properly. Validation process refers towards EU/USFDA guidelines, which is complex and may not be suitable of MSME industries in its present state. As per testing laboratories are concerned, it includes the involvement of both government approved NABL accredited labs, as well as EU/USFDA approved labs for validation. It is also not clear, if the quantification of recycled material used – to be regulated in the labels or not. A strong networking is required between Industries and regulators for the success of this amendment.

PRESIDENT - R&D/INNOVATION at Yansefu Inks And Coatings

Mr. Neelakamal Mohapatra, M. Tech. in Chemical Technology from HBTI, Kanpur, India is a R&D, IPR and Product Safety Regulation personnel with 22 years of research experience primarily in the Printing and Packaging sector.

He focuses towards developing cutting edge products and processes for Flexible Packaging application. He has worked in various capacities with renowned printing ink, coating and adhesive manufacturing, and IPR organizations; and currently working with Yansefu Inks and Coatings Pvt. Ltd in the position of President-R&D/ Innovation.

His research work has been published in journals of national and international repute. Few of his innovations has also been patented. He has 30 publications and 16 patents registered on his name. His special interest in promoting product safety regulation (PSR) within printing inks and food packaging industries have been well acclaimed by various organizations.

Mr. Jitendra Kumar Sharma is a Science and management postgraduate and a very well-known figure in the local as well as global printing ink, adhesive, and packaging industry. His years of experience through knowledge of printing ink formulations, its application in various printing processes such as Gravure, Flexography and Offset etc. have been well acclaimed by thousands of converters and ink, coatings, and adhesive manufacturers and their raw material suppliers. With various capacities he has served the Industry by associated with leading ink manufacturing brands. Currently he is leading the Yansefu Inks and Coatings Pvt. Ltd. team as the CEO, and also contributing towards promoting food-safe inks and coatings within the packaging fraternity.