Polypropylene is a wonderful material for Packaging. Its inert, has high stiffness, good clarity and lower density. The material has made inroads into host of applications in Packaging. Given the fact that PP requires less energy to produce and has high recoverable energy (calorific value), and is fully recyclable, it has natural preference to value chain players to use it for variety of applications.

In today’s competitive marketplace where consumer & Brand Owner want best functionality and shelf appeal & converter wants to meet those requirements at high conversion speed & energy savings, thereby making it more sustainable, the challenge become tough and role of clarifier become very important to make the packaging more sustainable and environment friendly.

Polypropylene clarified with old generation or 3rd generation clarifiers also require high stock temperature for converting technology.PP Clarified with Next Generation Clarifier technology enables Polypropylene to be processed at lower temperature as compared to competing materials. This is because Millad® NX™ 8000 has improved solubility characteristics and it can form fibrous network at lower temperature. This creates a broader, more robust processing window and a dramatic improvement in the clarity of polypropylene-molded product.

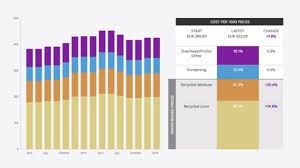

This aspect of Millad® NX™ 8000 has been recognized by UL Laboratory. The clarifier has received a clear distinction in the form of UL Label which says “Millad® NX™ 8000 enables an average of 10% energy savings for production of clarified PP parts”. Any converter or Brand owner (after completing necessary formalities with UL Lab under guidance from Milliken Chemical) can put this label on their part for differentiated product offering to the consumer.

The validation qualifies Milliken and eventually its customers, from converters to brand owners, to use an Environmental Claim Validation (ECV) label to highlight the energy consumption reductions achieved with the use of Millad® NX™ 8000 in a transparent PP product.