There are two different types of stretch wrap, the first is blown stretch wrap and the second is cast stretch wrap.

These two types have their similarities, but there are also several differences between them.

As the name suggests Cast stretch wrap is manufactured by a cast extrusion process, which starts with a granular polymer resin heated screw barrel & molten resin is continuously fed through a narrow slot die on a chiller roller. after that film cool & solidify quickly.

As the name suggests Cast stretch wrap is manufactured by a cast extrusion process, which starts with a granular polymer resin heated screw barrel & molten resin is continuously fed through a narrow slot die on a chiller roller. after that film cool & solidify quickly.

Blown stretch wrap is manufactured by a blown film extrusion process. which starts with a granular polymer resin heated screw barrel & molten resin is continuously forced into a circular die. Afterward, the hot resin is vertically blown upward and outward, which is typically referred to as a bubble. this bubble is cooled by chilled air and then slit into roll form. the cooling rate is lower than cast film

Blown stretch wrap is manufactured by a blown film extrusion process. which starts with a granular polymer resin heated screw barrel & molten resin is continuously forced into a circular die. Afterward, the hot resin is vertically blown upward and outward, which is typically referred to as a bubble. this bubble is cooled by chilled air and then slit into roll form. the cooling rate is lower than cast film

Every application is different from others thus there is no single best film if we compare both types!

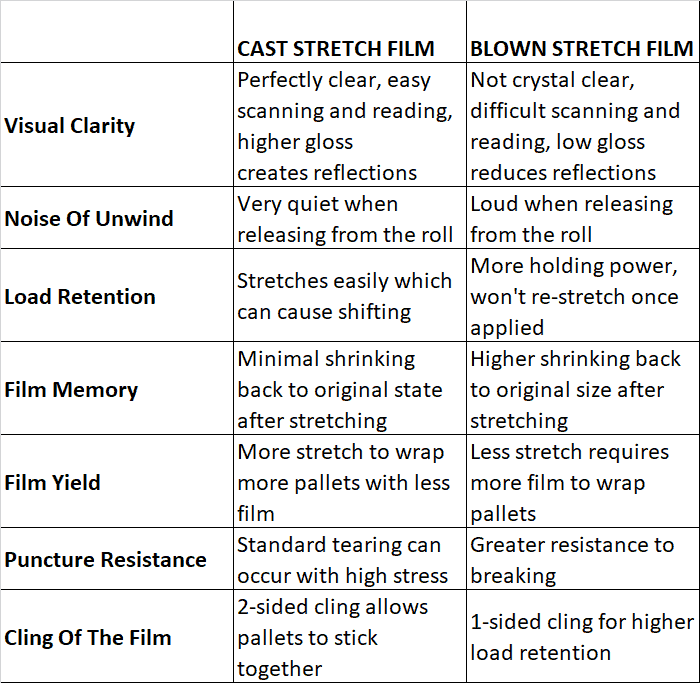

Clarity

Cast stretch wrap is extremely clear and produces the highest levels of clarity. By casting the molten resin over a frozen roller, crystallization is reduced and a clearer film is produced. Blown film is cooled slowly, which increases crystallization and reduces the clarity.

Film Memory

When PE is stretched, the molecules within the stretch wrap excite, which causes the stretch wrap to retract. In comparing blown and cast stretch wrap, the blown stretch wrap has a much higher degree of memory.

The orientation of the molecular chains produces a blown stretch wrap is on both machine direction (MD) & transverse direction (TD). Cast stretch wrap, however, has a single direction orientation (MD).

Film Yield

Cast film will stretch much further than blown film, which will allow you to cover more pallets with less film.

Images used in the case study are meant only for illustration.

The author is a Polymer Engineer & working as a Technocommercial professional for polymer raw materials. Previously associated the Manufacturing firm as a production engineer for blown film extrusion of Various kinds of plastic films like lamination film, Shrink film, stretch wrap, surface coating (masking film), Tube laminates, and Clingfilm.