In an exclusive interview with Packaging360, Mr. AVDK Prasad takes us through the complexities of industrial & bulk packaging operations associated with sugar, India’s major food commodity. He illustrates how Premier Tech, through its innovation & portfolio of solutions is able to meet the challenges of this vital sector.

Packaging 360: India as you may be well informed, is primarily an agro-based economy & sugar is one of the most important commodities. Given the quantum of sugar produced in India, could you begin by giving us an overview or scale of operation of the filling, bagging & palletizing operations for sugar.

AVDK Prasad: Sugar industry is an important agro-based industry that impacts rural livelihood and India is the second largest producer of sugar in the world after Brazil and is also the largest consumer. Around 525 mills produced more than 30 million tonnes of sugar in the last crushing season. This corresponds of nearly a Billion bags of sugar packed in 50 kg bags. The logistics require to achieve consistency in terms of handling this volume of sugar is tremendous. This coupled with the fact that the packaging section is mostly dependent on labour, gives us a lot of opportunities to work with.

Specific focus of interest remains automating the Bagging, Palletizing & Loading section in the Sugar Mills to ensure maximum efficiency.

Packaging360: What are the key elements that need to be factored, when designing a complete solution for sugar packaging, filling, bagging & palletizing & transporting? You could allude to both characteristics of sugar grains, moisture in grains, etc. which could possibly influence speed & performance efficiency.

AVDK Prasad: Different grades of Sugar come with their unique set of challenges and we rely on our team to advise the customer through the process. One important aspect that is often neglected in the bagging of Sugar is the fact that certain grades require a level of protection in terms of ATEX. Most equipment’s sold in India does not carry the right level of protection and this is something we work closely with our customers so that they understand the risks.

Refined sugar poses its own challenges in terms of equipment, needs to be compliant with GMP, as well as protection from sugar dust, such aspects are sometimes overlooked.

Automation is the key to avoid repetitive manual tasks that impact the efficiency of bagging, palletizing and transportation of sugar there by leading to a safe work environment for our customers.

Our equipment is built to work within these challenges, and we are committed to deliver the safest & most efficient equipment from all our manufacturing locations.

Packaging360: What are the salient features of the machines designed for filling & bagging of sugar grains? In your portfolio, you have listed a wide range of machines & so could you let us know some of the unique features of your machines & how these can be tailored as per requirements?

AVDK Prasad: As you can see, the heart of the sugar production process is not just about raw materials, but the equipment too. No

matter how good the sugarcane quality is, it may not be able to generate the value it should if your equipment is substandard. So, what about your business? Are you ready to take a step towards the ever-changing 21st century?

One of the easiest solutions is to use an automatic bagging machine equipped with a bagging scale, which offers better packaging consistency, as well as better control of both the speed accuracy & efficiency of packaging. Additionally, the process will be much more hygienic.

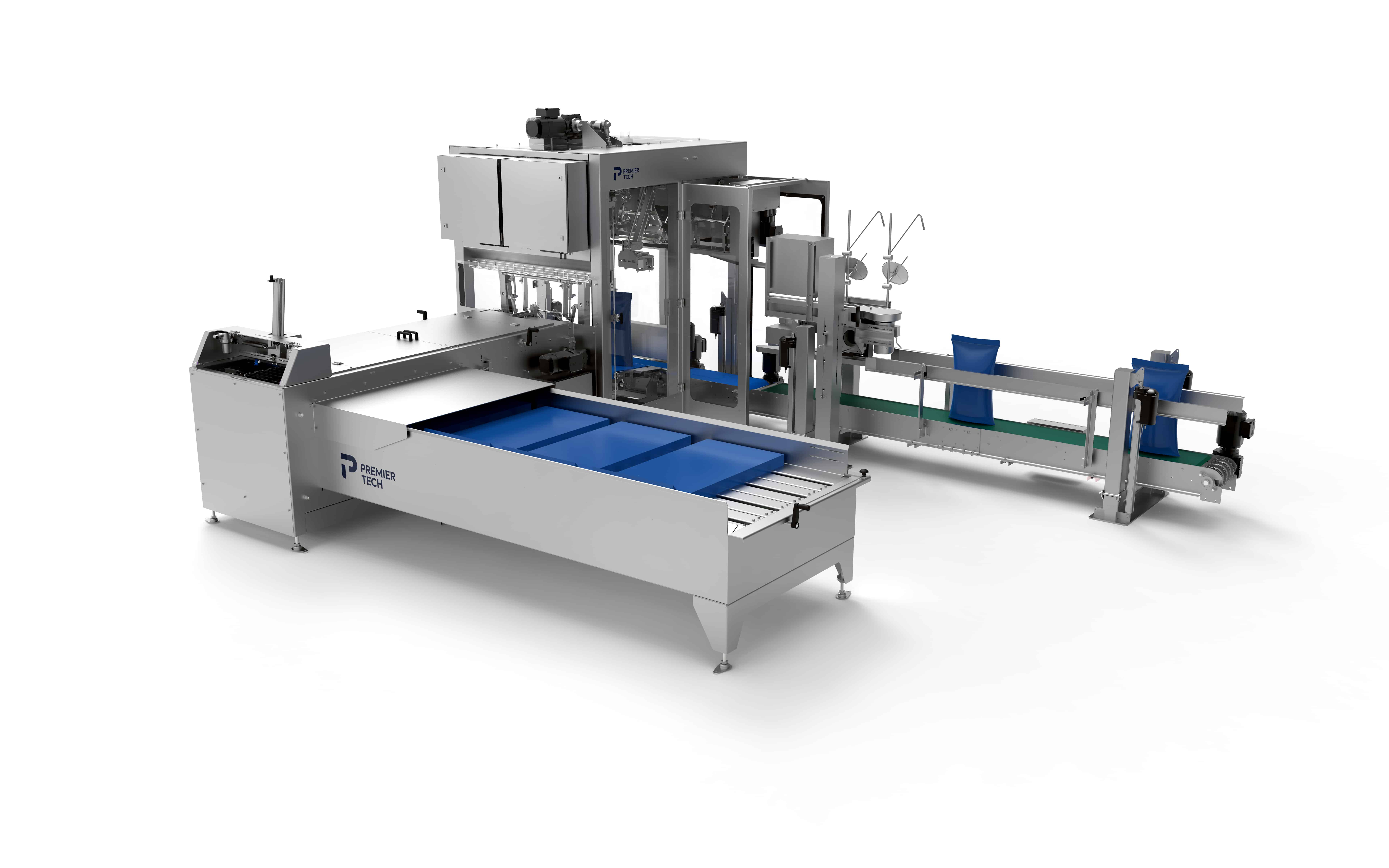

The easiest step you could take to improve the stability and accuracy of the entire packaging process is with the CHRONOS OML-1140 automatic bagging machine. It has a packing speed of up to 25 bags/minute with great accuracy. The deviation does not exceed 20g. as prescribed by the Office of the Cane and Sugar Board, and the machine can work 24 hours a day. Plus, there is a team of engineers and technical experts in India to provide after-sales service to assist and relieve the concerns of sugar producers. If you are interested to find out more about the CHRONOS OML-1140 automatic bagging machine.

Packaging360: As a global leader in the industry, how do you address issues like productivity, energy savings, automation for large – scale sugar packaging?

AVDK Prasad: The demands on modern machines and plants are steadily growing in all industries. With the automation systems from Premier Tech, you can cover all requirements while benefiting from maximum efficiency, flexibility, and cost effectiveness.

Sugar processing is an energy intensive industry that requires precise control and continuous reliability, especially during seasonal production cycles.

Premier Tech bagging machines are used worldwide for the packaging of sugar. Whether for large sugar producers or smaller ones, whether fully automatic or manual – we find the right system OML 1140 for each of our customers to meet their requirements.

Packaging360: Do you think the Indian sugar industry is ready for Industry 4.0 & if so, how do your machines fit the definition?

AVDK Prasad: “The 21st century” has become a term closely associated with technology and globalization. It should come as no surprise that everyone is trying to revolutionize themselves, as well as their businesses, through digital transformation and new innovations, in fear that they could be left behind otherwise.

The industry is right on the threshold of the fourth industrial revolution. Automation is being followed by the digitalization of production. The goal: an increase of productivity, efficiency, speed, and quality, resulting in higher competitiveness for companies on their way to the future of industry.

We have already begun with phase of this process with certain customers in India and we are working with them to help to understand the data and trends.

Digitization is a continuous process, and we are committed to work along with our customers to help them achieve their goals.

About AVDK Prasad

National Sales Manager – South at Premier Tech Systems & Automation, India, Certified Corporate Director, and IIM Lucknow alumni – Illustrious career spanning over 30+ years in techno-commercial engineering, mastered the art of international commerce, key financial practices, and global business customs – Gained successful business opportunities in the global market – Consistent at developing new business and driving innovation.

About Premier Tech

Premier Tech (PT) is among the largest packaging equipment manufacturers in the world and well-known in the flexible and the rigid packaging industries for its state-of-the-art packaging machines and its complete packaging lines for small- and large-scale production. Its wide product portfolio includes solutions such as bagging scales and feeders, bagging machines, case packing machines, robotic and conventional palletizers, stretch wrappers, stretch hooders, conveyors, etc. Moreover, PT also offers bulk processing solutions as well as peat moss field equipment, including screening systems, mixing lines, harrows, vacuum harvesters, etc.

Dr. R. Rangaprasad, is currently Business Head, Packaging 360, a Mumbai based knowledge service provider vertical under Catalyzing New Technology (CNT) Expositions & Services LLP. Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry (www.packaging360.in).

Dr. R. Rangaprasad is a chemical technologist by training having earned his Ph.D. (Tech) degree from UDCT (now ICT) in 1992.