Design Projects begin and end with Research. At every milestone, we do research to collect data – for Inspiration, Project Feasibility and Validation, all of which strengthen the roots of the project and design. Doing good research is winning half the battle

Every design service has its own course of research process though the ideology and approach are similar but the collection of data will vary. Designing structural packaging is a long cycle as it requires a huge amount of CAPEX, resource involvement and time. Hence it is critical that whatever we are designing is well-researched and stays on the shelf(Company’s portfolio) for a long period of time.

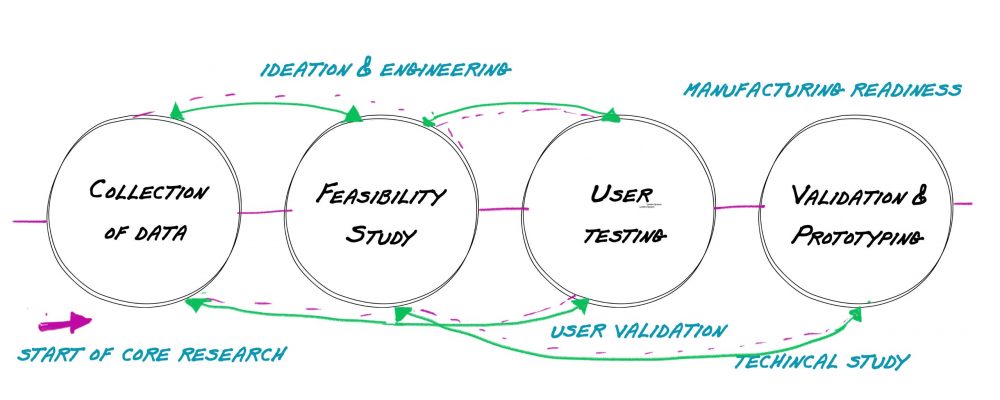

How does the research cycle sync with the overall project/design cycle?

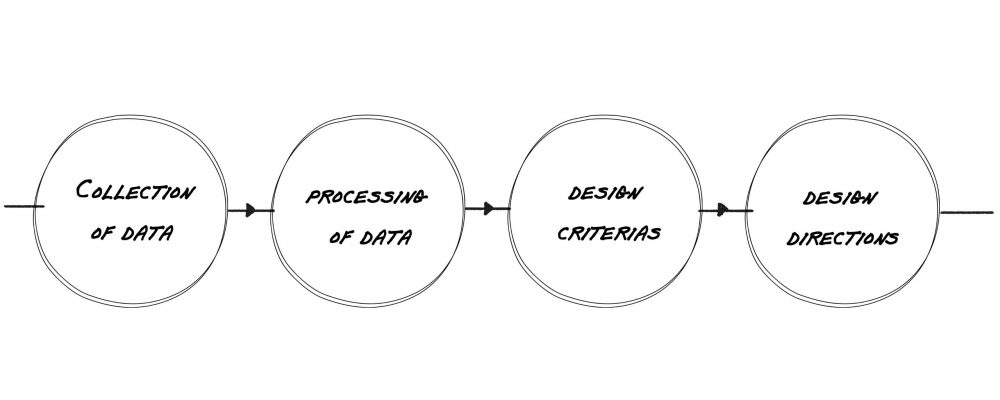

- Collection: It starts with the collection of data and processing it. This very collection of data helps us in constructing solid design criteria and builds a framework of must-to-have and nice-have features on the structure

- Feasibility Study: From ideation to engineering we try to seek some references which are already existing. Here it helps us to give a heads start and proof of concept

- User Study: What goes around comes around. User research helps is validation and building confidence to go for the next stage which is the production stage

- Execution: The last leg is the most crucial and highly depends on how well-researched you are to take your packaging to the execution stage. Here a lot of vendors and manufacturing-related interaction is a part of research and learning.

I believe the more you research, the more you know about constraints and opportunities. Research gives you a reality check and builds a framework. It’s your knowledge about constraints that help you outgrow problems and bring unique solutions to the table.

A key aspect of redesigning structural packaging is to bring a distinguishable form and experience to the shelf. To bring distinctiveness to the packaging we need to research what is already there in the market. Hence our first part of the blog is about how we are collecting and collating data that is already there and applying design intelligence to it.

In this blog, we will be focussing on the first leg of a research collection of data and churning it into Design Criteria. Research can take a week to months so we need to strategize the best collection method to expedite the project. Your research should yield results and create a framework for you to navigate easily through the next phase.

Collecting of data

Over a period of years and multiple projects, I find these are necessary topics to collect data from to build a wholesome evaluation list. This research can be applied to multiple materials and formats of packaging.

For understanding let’s take a use case of designing a bottle for drinking water which helps us relate better all the key data points.

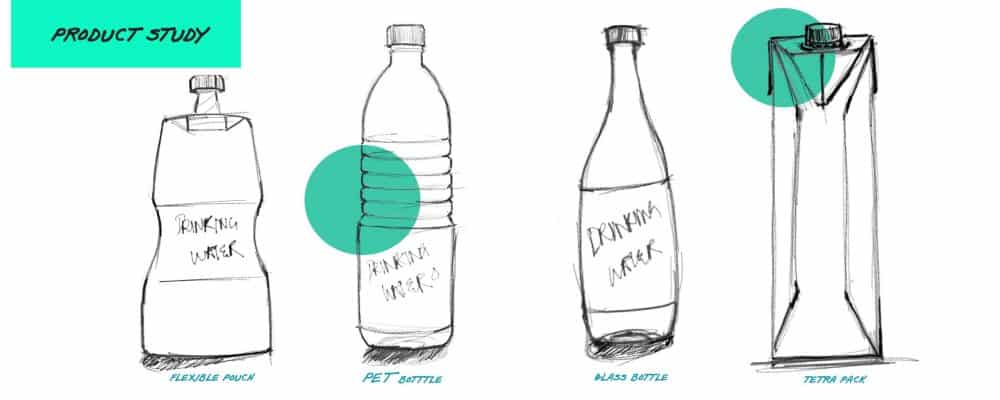

Product study: To know the characteristics of a product i.e physical, structural and chemical properties. This helps you to select the right material and specs for packaging. For drinking water, there can be multiple packaging materials that can suffice like Glass, plastic, tetra pack, flexible pouch, etc but if we change the product to an aerated drink then we need packaging material that can hold carbonation like Plastic, Glass, Cans, etc Product research insights help us in designing structural packaging that resembles product attributes, shape, USPs which in turn helps in distinguishing the packaging on the shelf.

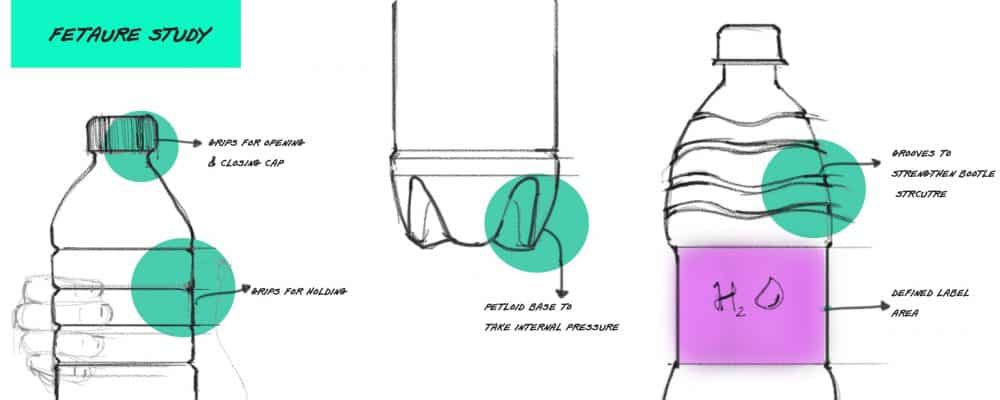

Functional/Feature Study: Diagnosing every part and detail of the structure. This entails understanding the features, dimensions, shape, and ergonomics of structure which needs to be designed for the entire operational channel. Structural packaging needs to withstand a long supply chain and be convenient for users as well for that a designer should be well-versed with the functioning of each part.

For eg: A plastic bottle containing water needs multiple features even for a small feature of providing grips to hold the bottle, a feature to place a label on the bottle during the filling line, providing ridges for structural strength and so on.

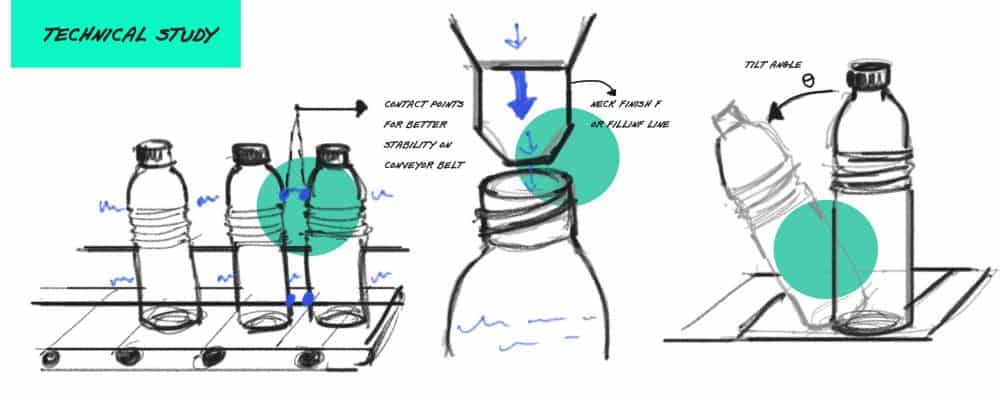

Technical Study: Researching the heart of a project where things will magically assemble. Understanding technicalities of filling and operation line. This study helps reverse engineer a few details. If you want to design a package that can be manufactured and work on the assembly line then you need to know the process.

Taking the drinking bottle as an example we need to understand nozzle dimensions to fix the neck dimensions of the bottle, what kind of labeling limitations are there, for stability on the filling belt – what kind of base structure is required and so on.

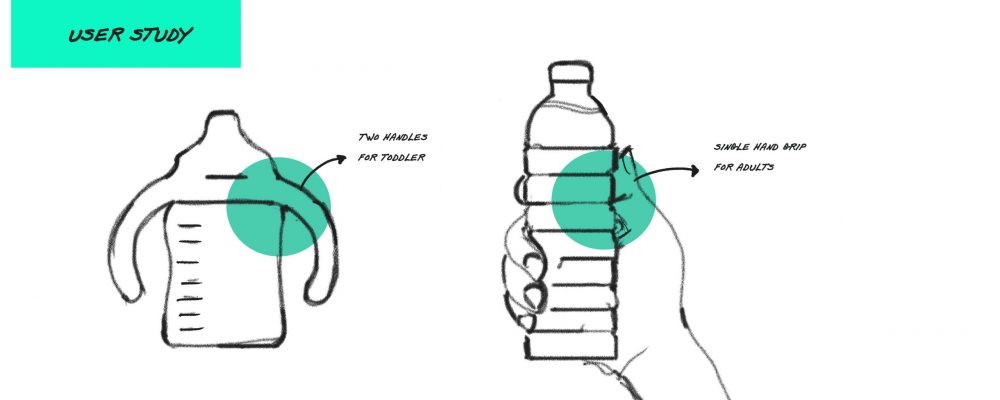

User study: Consumer research helps in getting emotional insights which is very much required to build a structure. To understand user persona, ergonomics and lifestyle become key aspects while designing the structure. When we do both quantitative and qualitative user research we are able to find patterns in consumer data which helps us to make objective goals in the design process. User research comes with a lot of reality checks of the likes and dislikes of consumers and designers have to take that with a pinch of salt with their aspirations of flying the project.

Depending on the project brief sometimes focus group sessions are held which helps designers to get continuous feedback during the entire course of the project. Here both getting a problem statement and validation is very important for consumers.

In the case of bottle design, the user could be a toddler and it becomes important to understand the ergonomics, activities, physical strength and mindset of a child. Here we can interview parents and take constant feedback into account while designing.

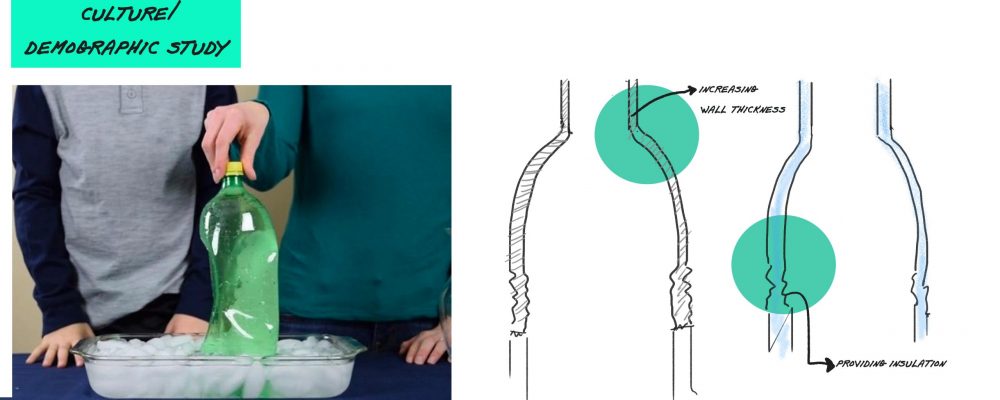

Cultural & Demographic study: Designers should definitely dig into the cultural and demographics study as it brings a lot of richness to the design and easy to market the product in that community. While designing the structure, designers can keep in mind- the availability of materials, specifications of materials and how procurement of materials will be possible. This will help to forecast challenges in the supply chain and what design features to be considered for all possible scenarios.

Taking drinking bottles as an example, maybe a brand is aiming to launch in northern regions of India. A bottle structure needs to be designed keeping climatic conditions like winter in mind. Maybe giving higher thickness to the bottle so that there are fewer chances of deformation or bulging and increasing the shelf life of packaging or by providing insulation to keep water at room temperature for a longer duration.

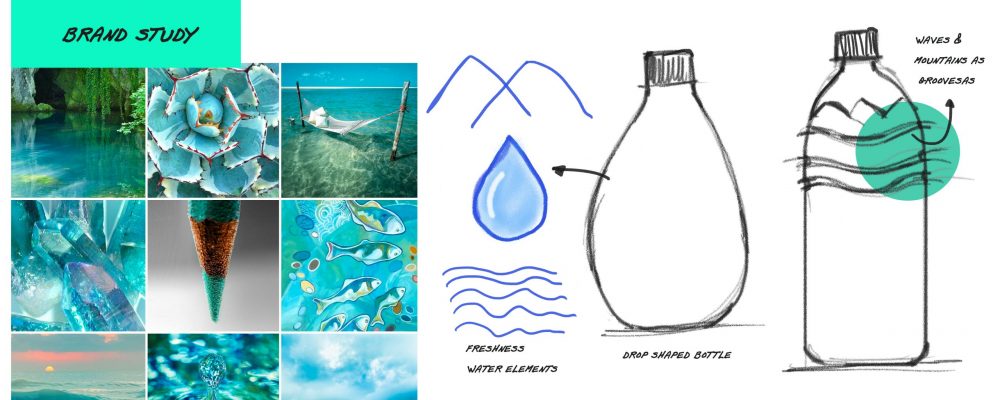

Brand Study: To understand brand ideology is very necessary. What are the values they want to call out through packaging? The brand study generally is more helpful to brand and graphic designers while designing artwork for packaging but structural designers also can align themselves with the values of the brand. Take softer attributes and bring them in the form and shape of the packaging, designing a form to provide appropriate branding space, highlighting logos on the structure itself, etc

If we take bottle design use cases- A brand wants to call out that the water has been brought from a freshwater reserve and bringing out those soft elements of nature on the bottle shape can help a brand convey to users freshness as a value.

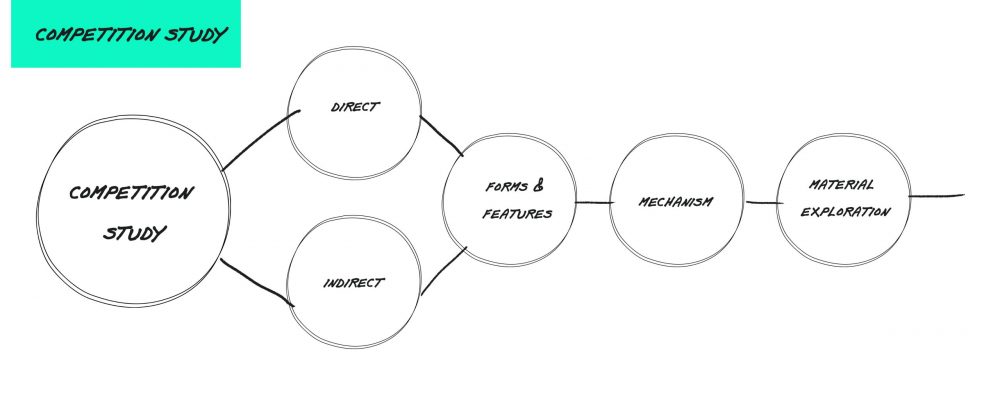

Competition: There can be two types of competition study one is direct competitors another is indirect/parallel products. Direct competition helps to understand brand positioning and references of what is already done which is working well for competitors or what gaps to work upon. Indirect competition is studying parallel products using the same material, manufacturing process, filling line, closure, ergonomics, etc. It is about taking references for certain features or shapes.

In the case of bottle design for water, we can study what direct competitors’ brands are using as packaging material, form, shape, weight, etc. We can also take the help of parallel products may be juiced, oils that use similar processes in designing and manufacturing. This also helps in eliminating any cross-reference product category duplication.

Processing the data

There can be multiple tools to process the data and draw inferences from it. Data is only useful if we apply intelligence and draw inferences from it. Here we come to the most interesting phase of research where we analyze and synthesize the data.

Here are a few steps that you can follow easily to analyze data and start using inferences for design directions.

Insight Mapping:

With every data collection under the above-mentioned topic, we can derive some

- Unique remarks- this helps us to bring unique features to the structure

- Common points- this gives a common and baseline for

- Aspirations

User journey Mapping:

Mapping highs and lows of users from picking a packaging- to opening-to unboxing-to using-to disposing of. This helps to map which area is more to focus, and where there are more gaps and opportunities.

Must-to-haves and Nice-to-haves

After collecting data we need to segregate what is critical and desirable. This helps designers to focus on resolving must-to-haves first and can easily progress or add nice-to-have features to the design if possible. This also helps align clients wrt expectations while presenting the concepts and how they can evaluate the best concept for their setup.

For example in designing the structure of a drinking bottle:

- Must-to-have could be maintaining the certain weight of the bottle, technical specs of the bottle, gripping area, label area, tamper evidence, etc

- Nice-to-have could be providing collapsible features, bringing out elements of water on shape, biodegradable material, etc

Design Criteria

This is the framework for your evaluation of the concepts. After deriving insights and technical data we should Ideally map all things in black and white or at least with approx values to be closer to ground requirements. These are defined critical features that need to be present in the structure. The same criteria can be used by clients and designers to evaluate the concepts.

From here the journey of Design directions and mood boards starts. Designers should know what data to be collected to derive inferences from it which is good research. Maybe in the above-mentioned list, only two to three will be required for a project and that is the call that designers should take while building a framework of research.

There is so much in research that we can dive into it and learn so much. It is also necessary that we apply our research and build better designs for the community.

“Research is seeing what everybody else has seen and thinking what nobody else has thought.” – Albert Szent-Györgyi

I'm an Industrial Designer with a specialization in Structural Packaging Design and Research.

Over the past 9 years, I have had the opportunity to work with multiple renowned brands, startups and have also collaborated with independent brands to conceptualize, mentor and implement innovative design strategies for their packaging.

As I am venturing into the packaging subject deeper and interacting with multiple stakeholders from concept to execution, I am learning to work on simple approaches and devising tools based on logical thinking which can make the design process enriching.