TUBEX Aluminium Tubes celebrated a key milestone in 2019 when it launched the Blue Tube Evo, the world’s first aluminium tube made of 95% post-consumer recycled (PCR) aluminium. Now the pioneering company is continuing its sustainable pathway by launching the Monotube. This latest addition to the portfolio is made of recycled aluminium from base to tip, and features a snap-off closure that can reseal the tube. TUBEX is glad to partner with REN Clean Skincare, a brand committed to more sustainable packaging, for this first application to market.

REN Clean Skincare leads the way by choosing the Monotube for eco-smart samples

Globally, in the beauty and personal care industries, 122 billion sample sachets are produced annually which are potentially incinerated or reach landfill every year. REN Clean Skincare is the first luxury beauty brand to offer its samples in the Monotube. By using the Monotube instead of difficult to recycle sachets, REN Clean Skincare is taking a further step towards its Zero Waste pledge: to only use packaging designed to be recyclable, containing recycled materials or being reusable.

As two companies deeply committed to protecting the planet, REN and TUBEX are natural partners. TUBEX is proud to be accompanying REN on its zero waste journey – and to be showing that luxury skincare and sustainability can absolutely go hand in hand.

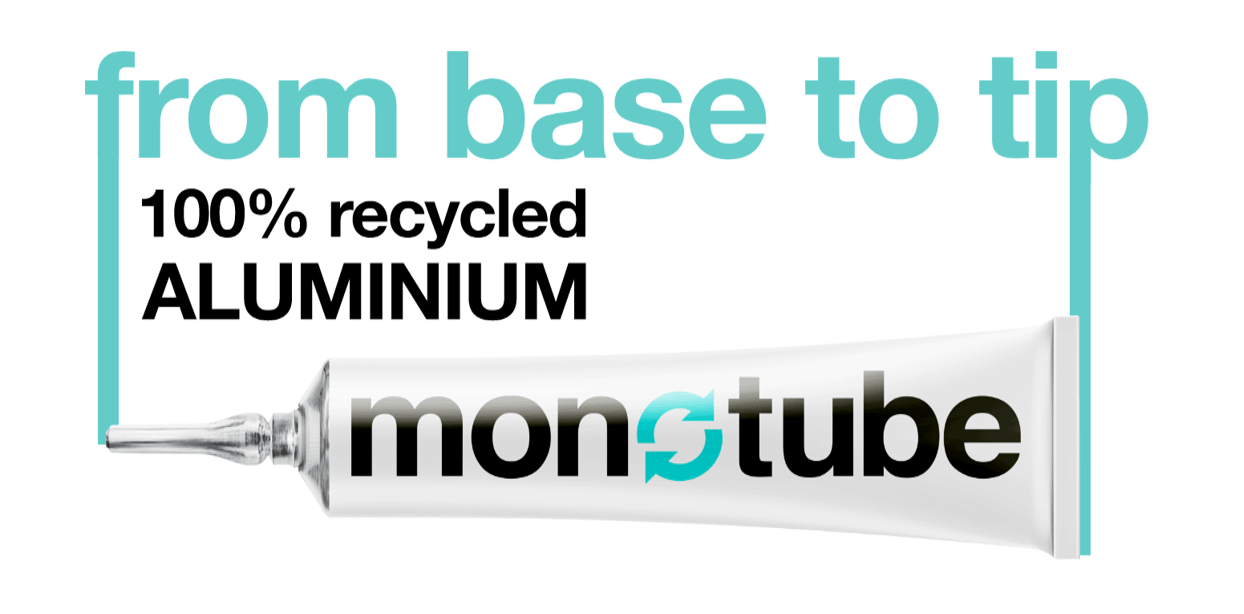

Aluminium from base to tip

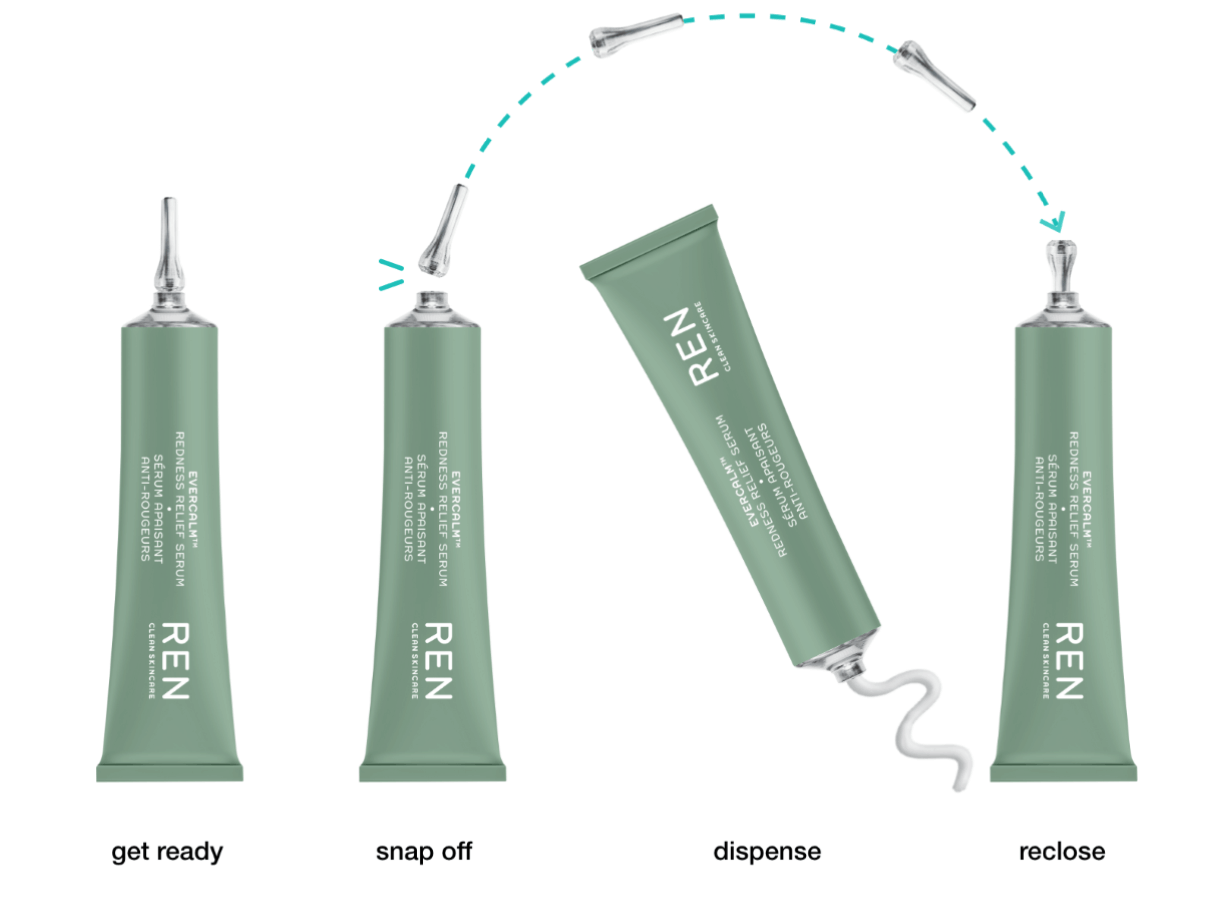

The Monotube is made of 100% recycled aluminium, 95% of which is PCR material and 5% is PIR (post-industrial recycled) material. It has an aluminium closure instead of a plastic cap, which makes the tube even easier to recycle. Because every part of the Monotube is produced from a single material, it is manufactured in just one production step that includes the closure – there is no need to separately manufacture and screw on a plastic cap. The Monotube’s clever design gives consumers the option of using all the product in one go, or resealing it temporarily.

A versatile choice

The Monotube is available in a range of sizes (sample-size, travel-size, single- or multi-use), making it a versatile solution for a wide range of products – from cosmetics and food to adhesives and medicines. Compared to conventional packaging for samples (e.g. sachets), the Monotube makes it much easier to dispense the product. And if the sample contains enough product for multiple applications, you can reseal the tube and use the rest later.

Premium quality, high circularity and low emissions

The Monotube provides excellent protection for both its contents and the planet. Aluminium has excellent barrier properties and is a valuable and durable material that can be infinitely recycled. It can be melted down and reformed time and again without losing its premium quality. An impressive 75% of all aluminium ever produced is still in use – and the recycling rate of aluminium packaging in Europe is 69%, which already exceeds the EU’s recycling targets for 2025.

The special developed aluminium alloy used for the Monotube, allows to close the loop by incorporating used aluminium tubes. Combined with a highly carbon-sensitive production across TUBEX’s supply chain this means that the Monotube is minimising emissions and scoring high on circularity.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.