Keeping healthy foods fresh and unspoiled often comes with an environmental cost in the form of plastic waste. But it doesn’t have to be this way, according to researchers from the Center for Nanotechnology and Nanotoxicology at Harvard T.H. Chan School of Public Health and colleagues at Singapore’s Nanyang Technological University. They’ve developed an alternative “smart” packaging material using biodegradable corn protein, starch, and other naturally derived biopolymers and nature inspired antimicrobials. It keeps harmful bacteria and spoilage microorganisms off of food and plastic pollution out of the environment.

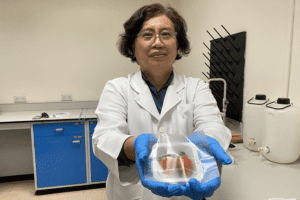

The packaging is made primarily from a type of corn protein called zein—which is produced from corn gluten meal, a waste by-product of ethanol production—and other bio-polymers that can be extracted from food waste. It contains a mesh of nanoscale fibers, which were produced through a scalable technology called electrospinning and infused with a combination of natural antimicrobial compounds including thyme oil and citric acid. The fibers were programmed to sense the presence of enzymes from bacteria such as E. Coli and Listeria and increased levels of relative humidity on their surface. In response to these conditions they release miniscule amounts of the antimicrobials to enhance food safety and shelf life.

In an experiment, strawberries that were wrapped in the packaging stayed fresh for seven days before developing mold, compared to strawberries that were kept in typical plastic fruit boxes, which only stayed fresh for four days. And because this protection is provided only when needed, the taste and composition of food in the packages is preserved. The results of the study were published in the journal ACS Applied Materials & Interfaces last October.

There is an urgent need to improve food packaging, according to the study’s co-leader Philip Demokritou, adjunct professor of environmental health at Harvard Chan School and director of the Nanotechnology and Nanotoxicology Center. Minimizing spoilage and waste will help provide the world’s growing population—expected to reach nearly 10 billion by 2050—with safe and nutritious food. And plastic is not a benign environmental nuisance. It degrades over the course of its lifecycle, and releases tiny fragments into the environment that end up in our air, water, and food, raising concerns for health.

“We need more research in sustainable, biodegradable smart food packaging like this so that manufacturers can start making these materials in a scalable way,” said Demokritou. “There are a lot of companies focusing on developing sustainable technologies and materials. And I’m very optimistic that we will see an escalation of their use in many products in the near future.”

The development of this novel packaging material is a result of a collaboration by scientists from the NTU-Harvard T.H. Chan School of Public Health Initiative for Sustainable Nanotechnology (NTU-Harvard SusNano). The five-year Initiative, which brought together more than 30 faculty from Harvard and NTU, funded five research projects focused on assessing the health effects from nano and other advanced materials and developed technologies to address inefficiencies in agriculture and food systems. Demokritou, who was the founding co-director of the initiative, joined the Rutgers School of Public Health and Environmental and Occupational Health Sciences Institute in 2021, where he is Henry Rutgers Chair and Professor in Nanoscience and Environmental Bioengineering.

The patented technology and material used in the smart packaging attracted the interest of industry, and efforts are underway for a potential commercial use, Demokritou said.

In another recent project, researchers at the Harvard Chan School NanoCenter and the Harvard School of Engineering developed a patented technology to synthesize a form of antimicrobial packaging that can be washed off of foods.

Researchers at the School’s NanoCenter are also exploring other ways to enhance food safety and quality, including a nanotechnology-based antimicrobial platform using their engineered water nanostructure technology.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.