The German technology group SCHOTT is investing an additional double-digit million-euro figure into a new glass tank at its tubing manufacturing plant in Jambusar, India. The expansion follows recent investments at the site including the construction of another additional tank facility just last year. Production of pharmaceutical FIOLAX® tubing from the new tank is scheduled to begin in the second half of 2020.

The capacity expansion is part of the company’s global growth strategy of its pharma tubing and packaging business segments. “The pharmaceutical market is booming worldwide with a very high demand for premium pharmaceutical packaging and tubing”, comments Dr. Patrick Markschlaeger, Executive Vice President at SCHOTT, Business Unit Tubing. “In order to supply the rapidly growing domestic and Asian market, we are investing once again a multimillion-euro figure in our Jambusar site to increase our manufacturing capacity in India.”

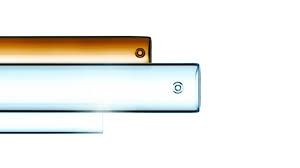

FIOLAX® borosilicate glass tubing features a high hydrolytic resistance, which makes it an ideal material for primary packaging of medicines. “Since its development in 1911, FIOLAX® has been established as the gold-standard material for pharmaceutical containers and its behavior with drugs is well researched and proven. In India, it is primarily used to manufacture glass vials and ampoules”, adds Sundeep Prabhu, Vice President Sales & Marketing Jambusar at SCHOTT Glass India Pvt. Ltd.

In line with the company’s aim to manufacture zero defect tubing, the tank will feature the unique big data approach perfeXion®. The process, which has been rolled-out globally by SCHOTT since 2017, ensures 100% quality control of each tube on the line by using cameras, laser and IR inspection systems. “In Jambusar we are combining Indian and European technologies and local skills. With the additional tank, we are also adding new workplaces,” explains Georg Sparschuh, Managing Director at SCHOTT Glass India Pvt. India.

The new tank will be built and equipped with the latest state-of-the art machinery according to the high standard of all SCHOTT Tubing production sites. Besides the tank facility, the investment includes an extension of the batch house, warehouses and a new chimney.

Source: Schott

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.