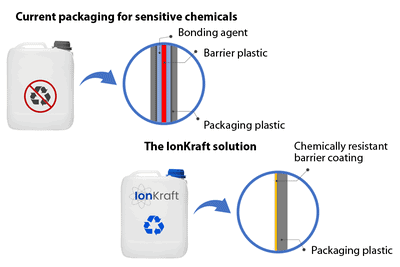

In April 2021, Montgomery Jaritz and Benedikt Heuer founded the deep tech start-up IonKraft, with the aim of using its technology in plant engineering. By means of plasma technology, the company wants to make plastic packaging for barrier applications in the chemical industry recyclable, and thus replace multi-material solutions. This technology has its origins in the research work carried out by the plasma technology working group at IKV on plasma-polymer barrier and corrosion protection coatings. Now, with IonKraft, it is aiming to find its way into industrial application.

Production technology for the coating of plastics by means of plasma

At the heart of the undertaking is the development and production of a reactor that coats plastic packaging and provides it with a chemically resistant barrier function. For the necessary process adjustments at the customer’s premises, a diagnostic-based development routine is available, the origin of which goes back to the IKV research work carried out in Collaborate Research Centre TR 87. Instead of performing empirical trials, coatings are developed on the basis of diagnostics. Consequently, IonKraft can guarantee the best functionality of the coatings to exactly suit the individual packaging.

The close cooperation of IonKraft with IKV and RWTH Aachen University is also continuing after the founding of the company: IKV’s measurement technology, laboratories and machines are still permanently available to IonKraft for carrying out complex tests and analyses. In addition, the business project was, before it was founded, thoroughly examined by an external jury of experts, and is largely financed by the German Federal Ministry for Economic Affairs and Energy through the EXIST research transfer programme.

Technology opens up a broad spectrum of application

The plasma layers applied by means of a newly conceived reactor generate a strong migration barrier, for example for solvents. The first reactor design should make it possible to coat pack sizes of up to 20 litres. This corresponds, for example, to the demand by the agricultural industry for the packaging of fertilisers or crop protection products. The advantage of the coatings applied by the plasma technology is that they can be applied extremely thinly to monomer materials and do not impair the recyclability of the pack. This effect can be utilised in many sectors and applications. In food packaging, for example, for which the process has already been approved, the coating acts as an oxygen barrier and prevents oxidising of the contents.

The plasma reactor developed by IonKraft is intended to be able to coat containers from both the inside and outside. A two-sided coating can thus, for example, serve as an odour barrier, which encloses the bad odour of recyclate. If an odour barrier is created through plasma coating, the field of application of recyclates can, on principle, be extended and the plastics cycle closed at a later point. In a separate project at IKV, research is currently being carried out as to what extent the coatings are suitable for making post-consumer recyclate safe for reuse in the food sector.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.