Monomaterial composites are regarded as one of the keys to improving the recyclability of plastic packaging. However, they cannot easily replace conventional multimaterial composites. Here’s what producers should look out for.

The purer a recycled material is, the easier it is to recycle. The best example of this is PET bottles, for which an established recycling stream has existed for many years. However, packaging often consists of several raw materials, i.e. either different plastics or even paper, aluminum, and plastics. It is very difficult or even impossible to separate this material mix during recycling – often the only option is downcycling, i.e. reprocessing to a lower-quality product. On the other hand, monomaterial packaging is easier to keep within the cycle. This packaging is made up of several films, for example, but the raw materials come from a single grade of material. However, manufacturers switching to monomaterial film composites should be aware of some specific requirements:

Definition of monomaterial packaging

Packaging is classified as monomaterial if it consists of only one basic raw material, for example, polyethylene (PE) or polypropylene (PP). However, it may be composed of different layers of the base material, each of which performs different packaging functions, such as strength. A small proportion of foreign materials is also permitted, providing it is not an obstacle to recycling.

Safeguarding packaging properties

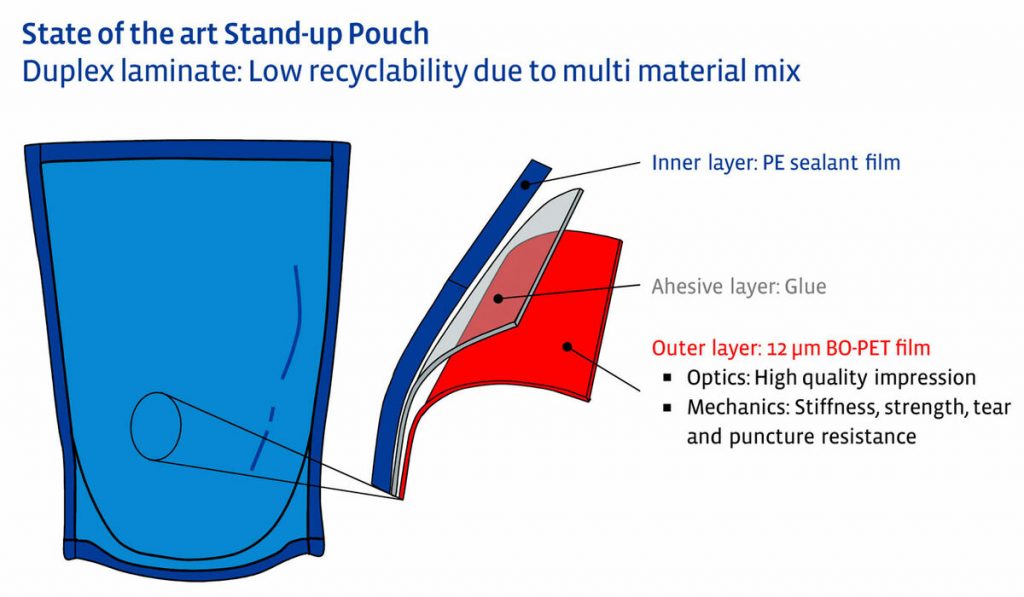

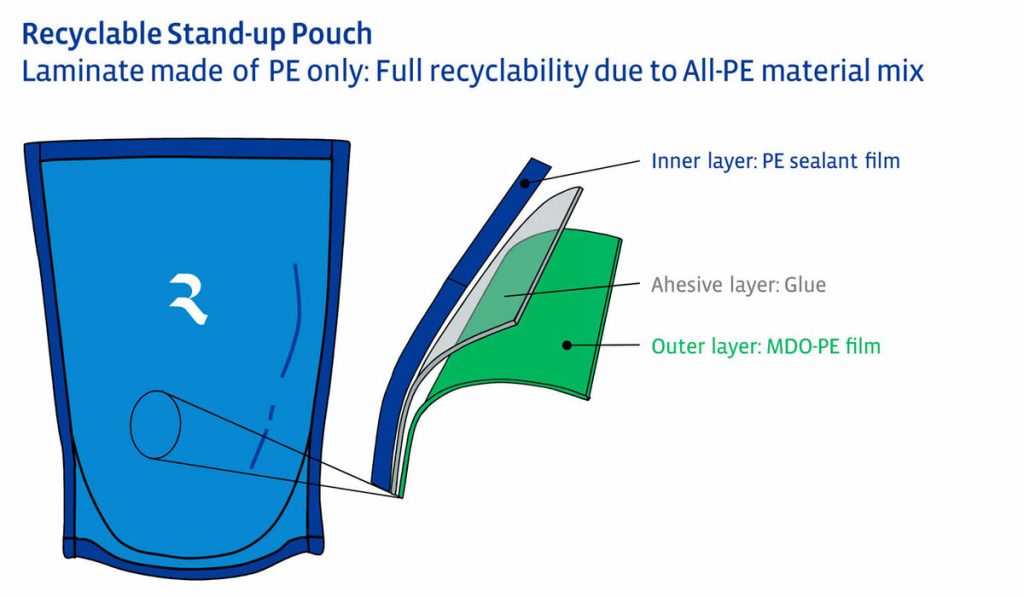

It is not sufficient for monomaterial film composites to be recyclable; in particular, they must meet the technical standards of the packaging industry. Therefore, films and layers made of different raw materials ensure mechanical and optical material properties – for example, the specified gloss, or the stiffness of the film to provide the stability needed by stand-up pouches.

Providing barrier protection

In addition, monostructures must be able to provide reliable barrier functions, such as a barrier effect against oxygen, vapors, and aromatic substances. For example, a change in the use of raw materials must not come at the expense of shorter food shelf life.

Allowing for downstream processing

It must also be possible to produce the monomaterial composite in a stable process without any loss of productivity and, ultimately, it should be easily convertible into packaging. This means that producers must be able to print or laminate the films without having to change their production process.

Monomaterial design: Film requirements are crucial

“There are many questions to consider when switching from multimaterial to monomaterial composites,” says Dr. Christoph Lettowsky, Senior Application Manager at Reifenhäuser Blown Film. “The answers depend on the requirements for the film downstream.” For example, PE monomaterial composites (all-PE film) are a promising alternative to film composites made from multiple raw materials for flexible packaging, such as stand-up pouches. Here, a number of different PE layers perform the various functions that are vital for conversion to the finished packaging product.

These film laminates can be produced using EVO Ultra Stretch stretching technology on Reifenhäuser blown film lines. In this process, the PET film that is otherwise required for stability is replaced by a stretched PE film. This is made possible by a five- to six-fold stretch rate, which gives PE films completely new mechanical properties. There is no need to adapt other processing steps, such as printing, lamination and conversion. Barrier materials can also be added to the stretched film, provided they are compatible with the recycling process.

Monomaterial pouch: The stretching unit is the key to success

The EVO Ultra Stretch stretching unit is also capable of stretching other raw materials – with greater stability and efficiency than alternative processes. The reason for this is the patented position of the EVO Ultra Stretch stretching unit directly in the haul-off of the blown film line: The film, still hot from extrusion, is stretched directly after flattening. This also extends the cooling phase before winding and gives the film the necessary time it requires to assume its new properties.

“On the other hand, stretching is not something trivial,” explains Dr. Lettowsky. “A number of machine parameters must be set correctly, and it also requires a certain amount of recipe know-how, since not every material can be stretched to the same degree.” Over the past few years Reifenhäuser has gained considerable experience in this field at its own Technology Center and in cooperation with customers, advising and supporting customers along this road.

Benefits of stretching

- Puncture resistance

- Stiffness

- Tear propagation resistance

- Barrier properties

- Breathability

- Downgauging

- Gloss

- Transparency

- Flatness

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.