Nongfu Spring’s latest additions to its beverage portfolio required a hyper-flexible and safe aseptic solution, able to process high- and low-acid, still and carbonated products in PET, while enabling impactful bottle designs. With four decades of supporting sensitive beverage producers worldwide, Sidel recently engineered and installed a complete aseptic packaging line, integrating the Versatile Aseptic Combi Predis™. The line helped the leading Chinese beverage player launch a breakthrough in the domestic market: sparkling Ready-to-Drink (RTD) products, aseptically bottled in PET.

Founded in 1996 in Hangzhou, Nongfu Spring Co Ltd. (Nongfu Spring) is one of the key players in the soft drinks market in China, maintaining leadership in the packaged water market over the past eight years. The company bottles not only high-quality natural drinking water, but also vegetable and fruit juices, functional beverages, teas and other high-quality soft drinks, including plant protein yogurt, premium water for elderly people and vitamin water. Its strong focus on innovation and premium brand positioning are contributing to the steady customer base increase, even within beverage categories.

The popularity of Nongfu Spring’s RTD tea and coffee products reflects a large, overarching trend across Chinese consumers, as they are showing a continuously growing preference for “better-for-you” products that either exclude sugar or include functional ingredients. Through innovative offerings, Nongfu Spring is the first in China introducing sparkling tea, juice, coffee, etc., aseptically packaged in PET and successfully serving these markets, which are offering promising sales opportunities.

Innovation-driven suppliers are key for premium beverage players

Nongfu Spring offers high-end, unique product propositions from bottle design to drink quality and recipe formulation to Chinese consumers and aims to enrich the product portfolio on a yearly basis. Sidel can thus fulfil Nongfu Spring’s mission as one of the strong partners that is able to combine forward-looking technologies with professional support.

The two companies rely on a robust relationship, as they have already been working together for over 10 years. Nongfu Spring renewed its trust in Sidel after looking for a highly flexible solution to handle both still and carbonated beverages, as well as low- and high-acid products on the same line without compromising on safety, simplicity, sustainability, and, especially, versatility. This is why a complete PET line featuring Sidel’s Versatile Aseptic Combi Predis came as a natural choice.

Flexible aseptic bottling thanks to dry preform sterilisation technology

The leading Chinese player was already familiar with aseptic bottle decontamination technology in a standalone configuration. And it also validated Sidel aseptic dry preform sterilisation solution in the past few years. This is efficiently supporting Nongfu Spring in the expansion of its portfolio, while ensuring reliability and product integrity. For further flexibility, the dry preform sterilisation technology solves the challenges presented by different bottle shapes, as the sterilisation takes place at the preform stage.

Additionally, the Nongfu Spring decided to equip the Combi with Sidel’s patented active base mould system, the Base Over Stroke System (BOSS), in order to differentiate some of its bottles and expand its marketing opportunities. In fact, the technology can be selected depending on the container’s shape. BOSS is a piston activated system in the blowing phase that strokes the base, thus raising and lowering it during the bottle-forming process, independently from the opening and closing of the two half-shells of the mould.

Nongfu Spring visited Sidel facilities in France and was impressed by the high-quality services and the long-standing expertise of the packaging team. They appreciated the support throughout project execution, starting from the validation of the new container shapes – with and without the BOSS base. In addition, Sidel’s liquid packaging interaction scientists performed various flavour tests for the new drinks Nongfu Spring were evaluating, thus defining the carbonation level and the sugar residue in the bottle. Then, once the line was installed, food technologists handled the microbiological validation of both high- and low-acid products, which successfully achieved zero contaminated bottles in 30,000 units on the first attempt, as per the protocol specifications. To ensure this success, Sidel experts and project managers made sure to closely support Nongfu Spring’s operators.

“For Nongfu Spring, it was critical to operate a simple and safe solution, while being able to manage the sheer variety of products in the future,” adds Mark Li, Technical Sales Manager Sensitive Products at Sidel. “The cost efficiency and sustainable benefits offered by our dry preform sterilisation technology were also key factors for them: using no water and very few chemicals, while pushing the boundaries of the lightweighting potential, represented a very valid argument with this leading company. Lastly, we were able to secure a very competitive lead time,” concludes Mark.

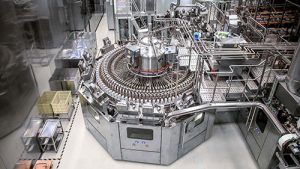

The new aseptic complete PET line at Nongfu Spring’s plant in Xin’anjiang (Eastern China) is running at 36,000 bottles per hour (bph). Aside from the Versatile Aseptic Combi Predis, it was also equipped with Capdis™, the dry cap sterilisation technology from Sidel. The line also includes Tetra Pak Processing Systems technologies, an easy-to-handle Sidel RollQUATTRO roll-fed labeller – for wrap-around labels – and Roll Adhesive labeller and a cooler with optimised water consumption. The End-of-Line solution integrates a wrap-around case packer and the modular PalKombi palletiser for medium to high speeds. Thanks to Sidel’s expertise in line design and engineering, deriving from its long-standing heritage in aseptic complete solutions for PET, the team at Sidel were also able to successfully and quickly cope with a very challenging line layout. It took merely three days to install the key pieces of equipment at Nongfu Spring’s plant.

Successful partnership leads to repeat orders

To quickly reach the committed line efficiency and maintain consistent volumes and quality of production, Sidel also ensured that two dedicated shifts of field engineers were working alongside Nongfu Spring’s personnel for 18 months.

Due to this fruitful cooperation, Nongfu Spring quickly decided to turn to Sidel again and invest in two additional Versatile Aseptic Combi Predis, installed in the company’s factories in Hubei and Zhejiang, respectively. Both equipped with BOSS and running even faster at up to 49,500 bph, those pieces of equipment have already been fully validated. Last autumn, Nongfu Spring acquired another Versatile Aseptic Combi Predis Combi from Sidel with speeds up to 54,000 bph.

|

|

|

|

|

|

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.