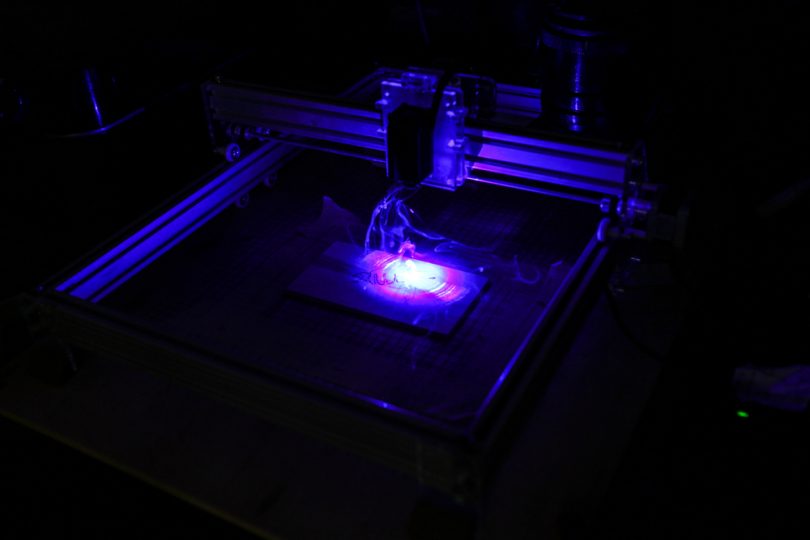

Clariant is set to develop laser-marking technology and materials in collaboration with pigment supplier Merck and resin producer SABIC.

The technology is expected to facilitate the recycling process for flexible polyethene, including low-density polyethene (LDPE) and linear low-density polyethene (LLDPE) packaging film.

The key partnership goal is to produce a complete supply-chain solution for laser-marking of films.

As part of the partnership, SABIC will provide its polymer technology for properties required in the film packaging and it will also supply its polymers.

Merck will focus on providing laser-sensitive Iriotec pigments and marking expertise.

Clariant will offer the additive masterbatch formulations for the film extrusion process.

Clariant Additive Masterbatches Laser global product manager Chun-Yip Pang said: “There is growing demand for clean, high-quality recycled PE, and while recycling rates for PE films continues to increase, there are still a number of challenges that need to be overcome.

“This collaboration is focused on eliminating the printing ink used for tracking, shelf-life, bar codes and other variable information that must be placed on almost any package on the market. Less ink means less contamination when it comes to recycling.”

The company also noted that the marks produced during the process are permanent and resistant to water, oil, grease or fatty foods and are suitable for mono-layer film or a laser-transparent surface layer.

Source : Clariant

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.