Elcoflex Ltd, based in Finland, an AIPIA member manufacturing copper based RFID antennas, has developed a new low-cost Smart Label concept based on a printed battery and readily available RFID chips. Current Smart Sensors use an embedded microprocessor system for analogue signal processing which, says the company, leads to a higher unit price.

Instead of using microprocessor based circuitry for temperature tracking, Elcoflex has replaced the microprocessor with an analogue transistor computing circuit and uses a standard RFID chip for data communication. The result is a low-cost disposable device that requires no modifications to current infrastructure, it is claimed.

The key component is the printed battery which gives the time base for the analogue computer. With a significant price advantage compared to alternative products available, the company believes this Smart Label opens a wide range of applications in item tracking, such as food freshness control; medical vaccine control; and logistics supply chain control.

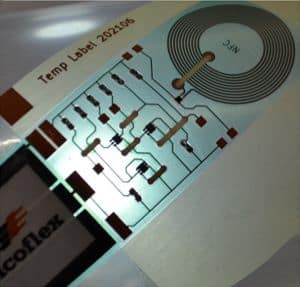

The Smart Label consists of a battery, the size of which can be adjusted according to the required time scale; a sensor, typically a thermistor for food chain control; an analogue computing circuit with precise temperature limit setting; a RFID chip equipped with tamper input; and a NFC or UHF antenna for communication.

The device will be manufactured on a high volume R2R antenna production line. Component assembly and chip bonding is also based on high volume industry standard equipment. The battery is based on environmentally friendly Zinc-manganese chemistry and the completed label is recyclable.

This concept is not limited to temperature measurement, any other physical content can be monitored if the sensor element is applicable to flexible format. For instance, temperature sensor can be replaced by humidity, UV-radiation, vibration or CO2-sensor as long as the sensors form factor allows assembly into the label format. Furthermore it is possible to reverse the alarm limit or arrange alarm between upper and lower limits. The fully electronic nature of this device enables even more sophisticated control algorithms.

In the next generation version of this Smart Label, analogue computer section will be integrated into the chip and overall size will be smaller. The mass production target price is below 20 cents.

Source: AIPIA

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.