Researchers at TU Graz develop green alternatives to fossil raw materials. Bio-based materials are expected to reduce pollution and drive the shift to a more sustainable economy.

As a renewable resource, wood offers great potential in the fight against the climate crisis. First, it sequesters large amounts of carbon (1 ton per cubic meter!). Moreover, it is an environmentally friendly alternative to fossil based resources, which cause the majority of greenhouse gas emissions. At the Institute of Bioproducts and Paper Technology at Graz University of Technology (TU Graz), researchers produce biodegradable materials from the wood components cellulose, hemicellulose and lignin.

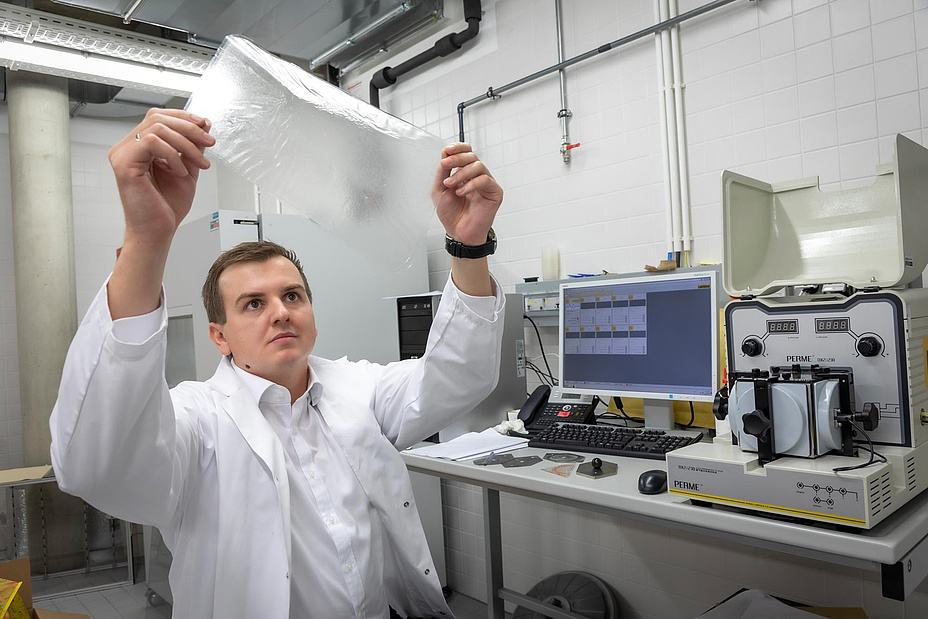

Samir Kopacic, for example, would like to use such materials to help ensure that in the future less plastic and more biodegradable materials are used. For this purpose, the Institute’s so-called “barrier lab” has been established in cooperation with academic and industrial partners. There, Kopacic carries out research on biobased packaging materials with barrier properties as good as those for synthetic plastics. They have to protect the package contents (food, cosmetics, medicines, etc.) from oxygen, humidity and other external influences, as well as to preserve the aroma and freshness of the products.

Currently, paper and cardboard are only suitable for this to a limited extent, as Kopacic points out: “Paper and cardboard are porous and fibrous. To achieve the necessary impermeability, they are often coated with synthetic polymers that are non-biodegradable and difficult to recycle, or laminated with metal foils.”

Learn more about Samir Kopacic and his work, as well as his career and motivations for going into materials research, in the Young Talent Portrait on Planet Research.

Kopacic would like to remedy this situation in cooperation with the Association of the Austrian Paper Industry Austropapier and with the support of its industrial partners. In the FFG research project PapSpray, which is funded to the tune of 810,000 euros, the project team is pursuing the approach of spraying paper or cardboard with biopolymers. “When applying bio-based barrier materials to paper, conventional coating methods have had limited success due to the complex flow characteristics of these materials. We are now testing the suitability of spray coating processes and investigating how biopolymers need to be sprayed onto paper to obtain the desired barrier properties,” says project leader Kopacic. For the young researcher (born in 1989), the conditions are right for a decisive breakthrough: “From a technological point of view, spray coating is a flexible process that can be integrated into paper production and can also be used in combination with or as a supplement to conventional coating technologies.” The three-year research project aims to develop a fundamental understanding of the interactions between paper, biopolymer and spray process, thus creating the basis for being able to produce and use plastic-free and recyclable paper packaging for an even broader range of applications than before.

Ultralight materials between materials engineering and biotechnology

The use of bio-based materials on a large scale is also the aim of the EU project BreadCell from the FET Open funding line, another research project at the Institute of Bioproducts and Paper Technology. Under the consortium leadership of Chalmers University of Technology (Göteborg, Schweden), an interdisciplinary team of researchers from TU Graz, the University of Vienna, BioNanoNet and the European research centre Tecnalia aim at developing a radically new technology for the production of environmentally friendly lightweight materials based on wood and cellulose. Currently, for example, large-scale industry uses mainly lightweight materials made of synthetic, non-degradable polymers for safety components in cars or for lightweight, robust and resistant sports equipment. “We want to offer alternatives and are working on sustainable cellulose foams to replace existing composites,” explains Stefan Spirk.

Spirk has already caused a stir with the development of a lignin-based redox flow battery (“vanillin battery”) and, together with Institute head Wolfgang Bauer, is contributing know-how from pulp and paper research to the project.

More about “Stefan Spirk’s ecological power storage using vanillin” can be found in TU Graz News.

Hermann Steffan and Florian Feist from the Institute of Vehicle Safety are supporting the project with their experience in the field of crash-proof materials in order to make the innovative materials usable with respect to safety-relevant applications.

The European Union is funding BreadCell to the amount of three million euros. Around 900,000 euros of this amount goes to TU Graz.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.