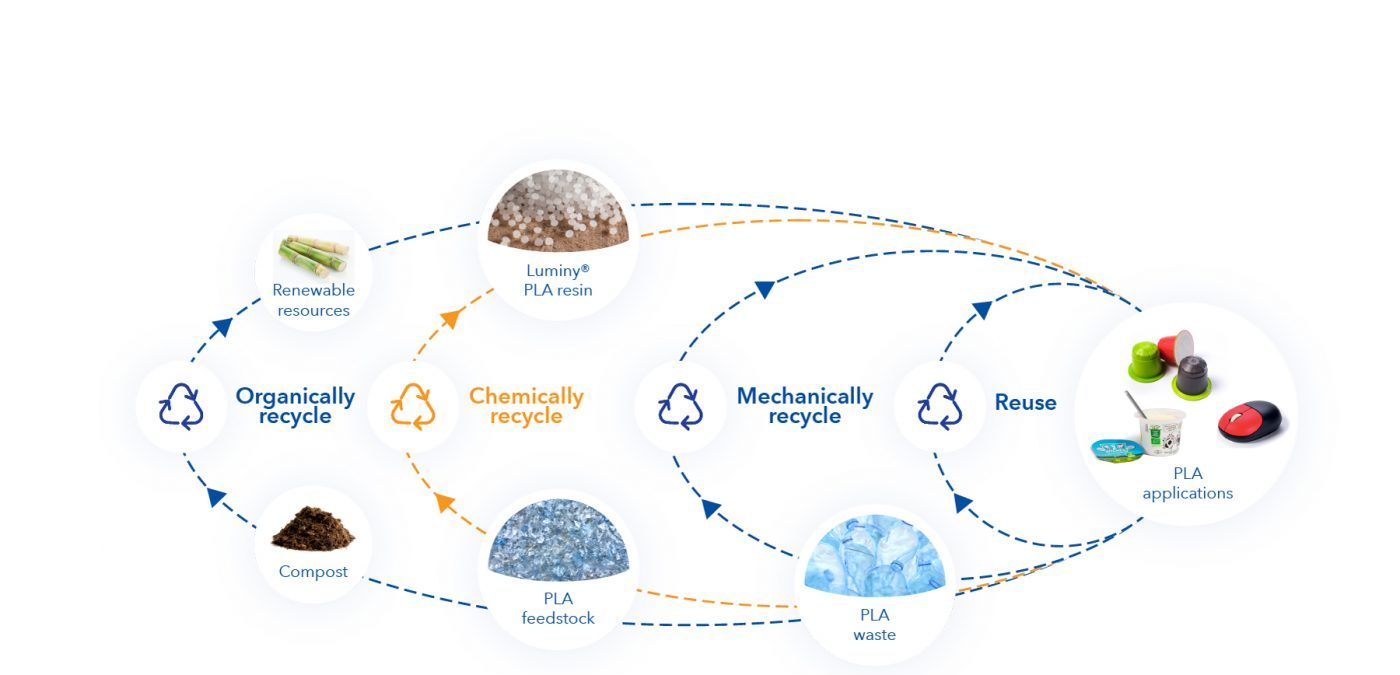

Total Corbion PLA has launched the world’s first commercially available chemically recycled bioplastics product. The Luminy® recycled PLA grades boast the same properties, characteristics and regulatory approvals as virgin Luminy® PLA, but are partially made from post-industrial and post-consumer PLA waste. Total Corbion PLA is already receiving and depolymerizing reprocessed PLA waste, which is then purified and polymerized back into commercially available Luminy® rPLA.

The commercial availability of recycled PLA (rPLA) offers brandowners the opportunity to make products from rPLA, with the luxury of having original food contact and other certifications in place. Using rPLA can contribute to meeting the recycled content targets of brand owners.

Thomas Philipon, CEO at Total Corbion PLA, sees this as a logical step towards an even more sustainable offering: “Our company’s vision is to create a better world for today and generations to come. This ability to now efficiently receive, repurpose and resupply PLA is a further demonstration of the sustainability of our product and the demonstration of our commitment to enable the circular economy through value chain partnership.”

François de Bie, Senior Marketing Director at Total Corbion PLA is proud to launch this new product line of Luminy® PLA and encourages interested parties to get in touch: “The ability to chemically recycle post-industrial and post-consumer PLA waste allows us to not only reduce waste, but also keep valuable resources in use and truly ‘close the loop’. For our customers, the new, additional end-of-life avenue this provides could be the missing piece in their own sustainability puzzle, and we look forward to solving these challenges together.”

As an initial offering, grades will be supplied with 20% recycled content using the widely accepted principles of mass balance. “As we are currently ramping up this initiative, the initial volumes are limited but we are confident that rPLA will grow to be a significant part of our overall sales revenues”, states de Bie. Currently, Looplife in Belgium and Sansu in Korea are among the first active partners that support collecting, sorting and cleaning of post-industrial and post-consumer PLA waste. The resulting PLA feedstock is then used by Total Corbion PLA to make new Luminy® PLA polymers via the chemical recycling process. Total Corbion PLA is actively looking for additional partners from around the world that will help to close the loop. We invite interested parties to contact their local sales representative.

Total Corbion PLA expects that the growing demand for rPLA will also boost the collecting, sorting and reprocessing of post-use PLA for both mechanical and chemical recycling, as de Bie explains further: “At Total Corbion PLA, we are actively seeking to purchase more post-industrial and post-consumer PLA waste, creating value for the recycle industry as a whole.”

Photo 1: The closed-loop end-of-life solutions enabled when using Luminy® PLA now also include chemical recycling.

Photo 2: Gerrit Gobius du Sart, Corporate Scientist at Total Corbion PLA, inspects the first batch of

chemically recycled Luminy® rPLA pellets.

Photo 3: Sansu are one of the first PLA customers to provide reprocessed PLA waste to Total Corbion

PLA for chemical recycling at the end-of-life of their bioplastic water bottles. http://www.sansu.co.kr

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.