Idvac Ltd., a world expert in advanced vacuum and thin film technology, has been investigating the application of the properties of some Liquid Crystals for packaging and security applications. Liquid Crystals are molecules which have properties between those of conventional liquids and those of solid crystals. They can be aligned by an applied electric field or other methods which changes their optical properties.

With industry becoming more anti-counterfeiting conscious, the demand for products with special overt optical features is escalating. Over the last few years, there has been a dramatic increase in the development of products containing colour shift features using different techniques. Colour Shift effect can be used for brand protection, anti-counterfeiting, and smart packaging in multiple industries, including banknotes and pharmaceuticals.

Colour shift effect is produced in nature by different mechanism including pigments, light absorption and interference as well as by a mechanism called photonic crystals. In industrial applications various methods have been employed to reproduce such effect. These methods rely on physical, chemical, and mechanical principles. They include optical absorption, interference, micro-structuring and light scattering.

Optical coatings consisting of one or more layers of dielectric or metallic materials, are widely used in applications ranging from mirrors to eyeglasses and interference filters. Many conventional dielectric coatings rely on Fabry–Perot-type interference[1] involving multiple optical stacks of transparent layers with thicknesses of the order of the wavelength to achieve functionalities such as anti-reflection, high-reflection and interference.

Opaque, inorganic based colour shifting Fabry-Perot structures have been used for many years and have excellent colour shifting effects. Typically, structures of this type are made by a vacuum depositing upon a substrate, a reflector layer and a dielectric layer followed by an absorbing layer. Such products appear highly reflective from one side due to the presence of a reflector layer and appear highly reflective with a colour that changes in an angle dependent manner when viewed from the opposite side due to the Fabry-Perot structure.

Iridescent Flakes used in paints and inks can be obtained from symmetric Fabry-Perot1 structures of the type Absorber/Dielectric/Reflector/Dielectric/Absorber. In this multi-layered stack, two single Fabry-Perot structures share the same reflector. By stripping off the deposited layers in the form of Flakes from the substrate and subsequently dying the Flakes, these Flakes can be printed on the required film. Such Flakes can be made opaque or transparent and can be used to make colour shifting paints and inks.

Another process used to produce colour shift effect is called Refractive –type multilayers. These consists of a limited number of deposited layers (from 3 to 9) with large differences in refractive index to produce a stack of high reflection. An example is the optically variable

[1] The Fabry–Pérot interferometer is an optical cavity resonator made from two parallel reflecting surfaces. It only transmits light of its resonant frequency.

ink. When the average refractive index of the coated stack is sufficiently low, the refractive –type interference structure combines a considerable reflection with a strong iridescent colour shift. This can be done by either having the all dielectric stack which consist of high and low refractive index or the metal-dielectric stack which is opaque. The metal-dielectric stack combines dielectric and metal layers (e.g. Al or Cr). This combination can be used to produce optically variable ink with high reflectance colour shift effect. This type of ink is currently used on some banknotes.

However, all the above processes require vacuum depositing equipment and involve a lengthy process to get the final result.

On the other hand, Liquid Crystals (LCs) are materials that have the properties of both crystals and liquids. These materials show order and mobility at molecular, supramolecular and macroscopic levels. LCs are accepted as the fourth state of matter after the three classical states of matter: solid, liquid, and gas. LCs are ubiquitous in everyday life in the form of LC display devices, thermal sensors and so on.

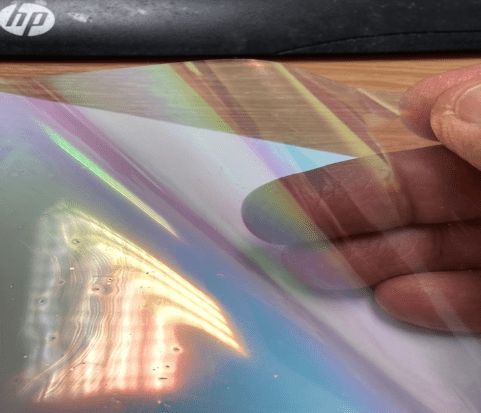

In our recent work we have developed a colour shift effect on a flexible film such as PET using Liquid Crystals and without the use of structural embossing, inks or pigments. The product exhibits an aesthetically appealing colour shift effect from red to green depending on the angle of viewing. The Liquid Crystals can be applied using different coating techniques including printing. After application on a flexible film, the LC coating is dried and UV cured to become solid at room temperature. The colour shift film produced is transparent and can be recognised in transmitted and reflected visible light.

This Idvac new development has the following features:

- Single layer application of LC on PET film using standard wet coating application methods such as printing.

- The LC colour shift film can be transparent or semi-transparent.

- Fast colour change from red to green.

- The LC colour shift film is bright and has saturated colours.

- The LC colour shift effect is easy to observe from a distance and from a multiple viewing angles under standard lighting conditions.

- The effect can be combined with other security features such as a holographic security pattern and a tamper evident layer to make unique products.

- The LC colour shift effect can be applied on high refractive index (HRI) coated films for extra reflectance and colours.

- The LC colour shift film can be laminated on Idvac vacuum metallised black coated films to achieve a Green/Deep Blue colour shift.

- The LC colour shifting film exhibits some polarizing effect when rotated from one angle to another under polarized light.

- The production of the LC colour shift film does not require vacuum metallising equipment.

Idvac Ltd., which is based in Manchester Science Park, England, has over 25year experience in the holographic and 40 year experience in advanced vacuum coating technology markets helping leading companies in the UK, Europe, USA, Asia and Far East to improve the image, brand and durability of their products. The company develops new processes and supplies process know- how and retrofits to convert standard vacuum metallizers to produce unique coatings.

Company Press Release

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.