Speed, sustainability and flexibility are getting important rapidly in the field of packaging printing. Due to this, the use of a variety of colours to meet the legal requirements for both the European and North American markets is a disadvantage.

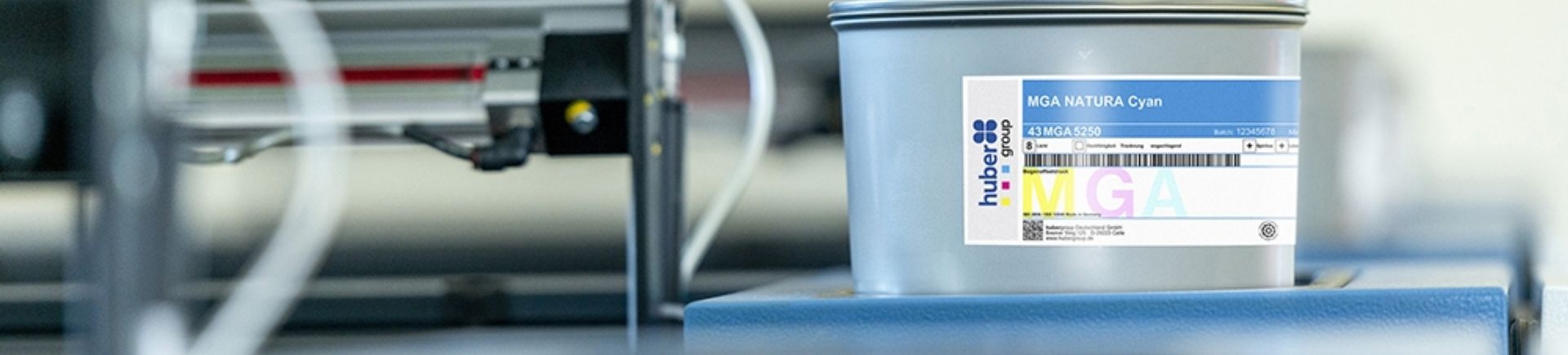

To simplify these processes, the Germany-based hubergroup GmbH has reinvented its MGA Natura ink series and developed a new printing ink which is said to meet all FDA standards and EC regulations for folding cartons of food packaging.

This would enable reduced approval cycles and increased production flexibility for brand owners. Furthermore, print shops and finishing companies no longer need to stock different colour types and undertake costly, time-consuming press wash-ups when packaging is destined for different global regions.

These new process and spot color inks consist of substances that will not migrate or which have been approved for food contact and are globally available commencing in January 2019.

“Our R&D staff did a terrific job, when they invented this single global ink formula!” says Taner Bicer, Chief Technology Officer. “They were able to identify, gain approval for and introduce the substance, while significantly improving printability and lowering migration risks, thus exceeding regulatory requirements in many regions, and meeting stricter requirements in others.”

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.