In the pharmaceutical industry, high-speed vial filling and packaging has always been a problem, especially during mass production. While coronavirus is raging around the world and humans could not find a panacea, we could only turn to vaccines for immunity.

Until today the effectiveness of vaccines has been widely recognized, but its capacity has been held back by packaging and filling speed and unable to meet the market demand for a long time;

In the past 20 years, Truking Technology has been committed to high-speed aseptic filling and packaging equipment. Truking have developed “High-speed vial transmission technology” to suppress impact loads, “High-speed and adaptive filling control system”, “AI Neural network Self-learning vision system” and “high-speed carton-opening device with multi-level planetary gearing”. As those developments help solve problems such as broken vials and low filling accuracy and support fast vial inspection and carton opening, they have been widely used in the market. At present, equipment applying above technologies have been integrated into a high-speed vaccine filling and packaging line. Operating in a stable and reliable way, a single line could produce 450,000 vials per day.

Following are details about above-mentioned technologies.

1. High-speed vial transmission technology to suppress impact loads

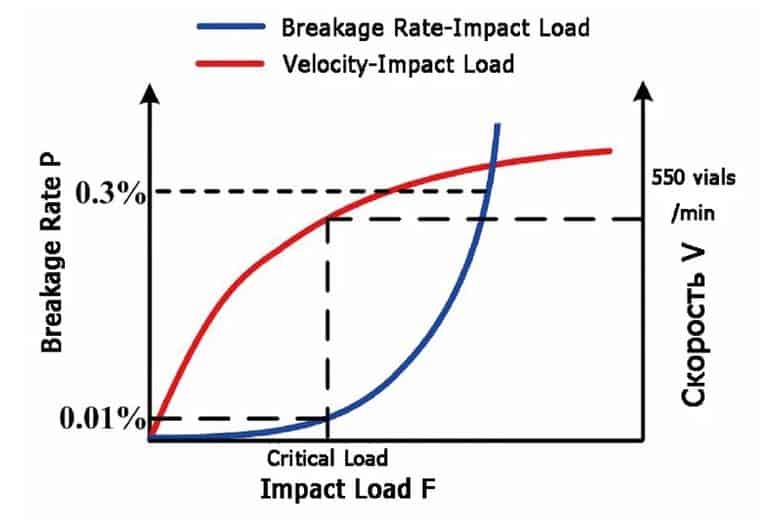

During high-speed (>550 vials/min) filling and packaging, vials with wall thickness of 1-2mm are subject to frequent impact loads during transfer, sampling, and rejection, which may easily lead to breakage. Through research, it was revealed that vials were broken due to the impact load caused by different driving and controlling strategies of independent units during equipment operation. After analysis of the optimal control criteria for protection of vial breakage in high-speed motion, Truking team has invented technology to control and coordinate transporting trajectory and speed, reducing breakage during high-speed filling. With the technology, breakage rate of a whole line can be ≤0.01% at a transfer speed of 550 vials/min.

2. High-speed and adaptive filling control system

High-speed filling has always been a problem that plagues the industry. The main difficulties are in tracking filling needles and assuring accuracy in filling volume.

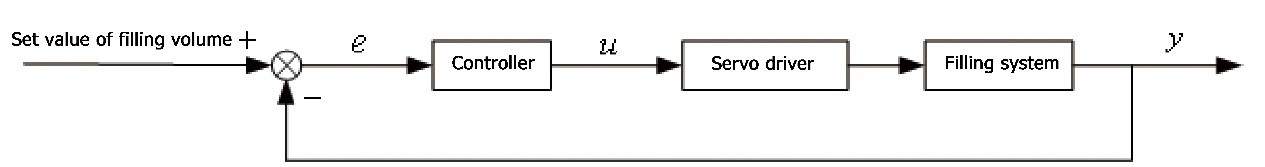

Truking has developed an adaptive and high-speed filling control system to ensure a stable and reliable mechanical structure. At the same time, it has been studied and analyzed the filling characteristics under different controlling algorithms to obtain the best controlling strategy, improving filling accuracy.

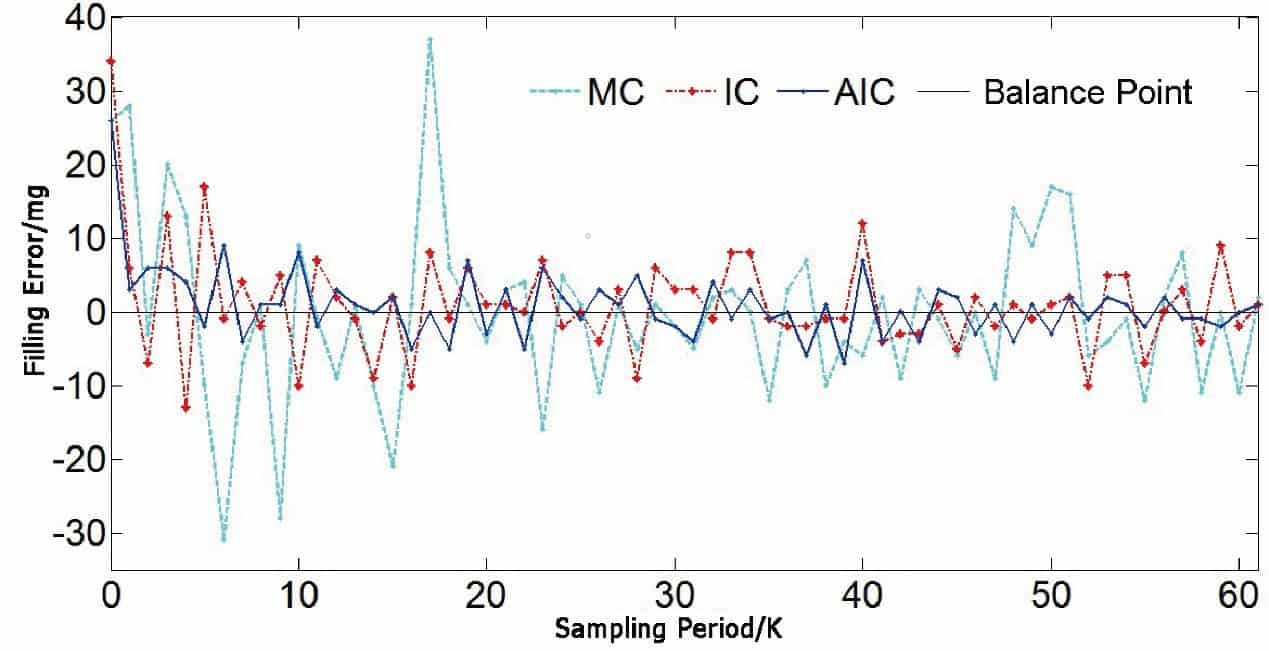

Based on studies of adaptive control laws, it was designed the adaptive controller (AIC) based on intelligent control (IC), which could detect trend of increasing deviations due to system’s time-varying, and track the non-linear characteristics of the filling system. By locally linearizing the global nonlinear characteristics of the system, it can be more effectively reduce the filling control deviation and improve filling stability. According to experiment data (Figure 4), compared to IC and MC, AIC can better improve filling accuracy.

3. AI self-learning vision system

Image comparison is the major method used to detect foreign bodies in vials, but it could falsely detect bubbles and thus leads to repeated detections. Truking has developed AI-based vision detection technology with embedded algorithms and neural network. With that, system could analyze mass samples and learn to distinguish bubbles and foreign bodies based on their shape, brightness, and trajectory. Handling 550 vials per minute, the system could detect stuff as small as 50μm with ≤0.01% false detection rate.

4. Flexible carton-opening motion control technology with multi-level planetary gearing

At present, the efficiency of vial packaging is mainly limited by the carton-picking and opening structure. To address this technical problem, Truking has developed a flexible carton-opening motion control technology with multi-level planetary gearing.

While developing this technology, it was analyzed designs and trajectories of planetary gears to build a gearing structure and conducted simulations to optimize it. Finally, the structure could, while operating in a stable reliable way, successfully pick and open 99.95% cartons.

After research, the above-mentioned technologies have been successfully applied to vaccine production equipment. The production speed of a whole line can reach 550 pcs per minute, and it can run at such speed for a long time. At present, the vaccine production equipment has been successfully used in various High-end biological products pharmaceutical companies around the world, such as China Biotechnology Co., Ltd., Russia PRV, India BB, UAE, etc., and more than 200 sets of production equipment have been put into use to provide powerful filling and packaging for the production of vaccine products.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.