GETEC.PARK EMMEN (GPE) releases this White Paper that provides insightful data how to control the product quality of recycled PET polymer and packaging. In addition, the right set of chemical analyses techniques to detect relevant substances and PET properties are discussed.

During PET production, product use and PET recycling, the PET product quality could deteriorate by:

- Thermal degradation

- The presence of solid contaminants.

- The presence of non-intentionally added substances (NIAS)

- Discolouration that affects the PET product appearance in visibility applications.

Therefore, cost-effective processing and obtaining the right and safe recycled PET quality is essential for both PET recyclers, PET packaging manufacturers and brand owners. Chemical analyses techniques are vital to monitor and control the quality of the (recycled) PET polymers and packaging. It contributes to improve product safety risks and saving costs.

The White Paper explains in-depth how:

- Melting steps during PET recycling can give rise to the occurrence of relevant NIAS. By means of Headspace Gas Chromatography (GC) such substances can be detected accurately. In this way, the rPET purity can be monitored. Recommendations are given to improve the purity of recycled PET.

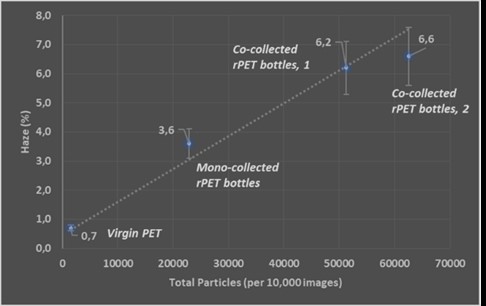

- The presence of solid particle contaminates arising in rPET can be detected by the unique GPE Partisol analysis. It is shown that the haze in PET packaging increases linearly with the total number of solid particles in PET. In addition, over 70% of the detected solid particles are 1 – 3 µm in size. Recommendations are given to minimize the presence of solid particles in PET to improve the PET transparency and minimize the crystallization behaviour.

Want to know more? Request a free White Paper copy!

Want to know more how GPE can help you improving the PET quality of your recycled PET and packaging? Request our free White Paper via contact@getec-park.nl

GETEC.PARK EMMEN (GPE) at a glance

GPE helps companies run their business processes efficiently by supplying utilities, engineering services, laboratory analysis and logistics. We do this for more than 70 years. The GPE laboratory is 24/7 in operation, performs over 125,000 analyses annually and employs 40 analyst professionals. GPE is an ISO certified lab offering over 950 different polymer analyses using a wide range of different analytical methodologies. Based on our decades-long expertise in PET and nylon polymer analyses, GPE can deliver analytical results fast. GPE is part of the Getec Group Company and is located in Emmen, The Netherlands.

Source: Company Press Release

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.