The flexible packaging and flexible films segments are growing rapidly in every industry, as producers of consumer goods find valuable advantages of the innovation. With its versatility, custom qualities, efficiency in conserving resources, and sustainability, there’s no better time to consider flexible packaging and flexible films for your new product line or as an upgrade to an existing package.

Here are five intrinsic benefits that flexible packaging and flexible films provide:

1. Flexible Packaging Film can be Customized

Flexible film is customizable based on the product’s features that have to be packaged. This solution offers flexibility to modify the brand’s packaging according to its market objectives and specs.

There are three main types of films: polyolefin, polyvinyl chloride and polyethylene, in order to offer security and protection to the products in shipping and retail environments. Each one comes with different characteristics and capabilities that make them ideal for particular applications, as well as they can be combined to make multilayer films offering distinct barrier properties for extending shelf life and improved protection. Flexible film can also offer tamper-resistance to packaged goods if required.

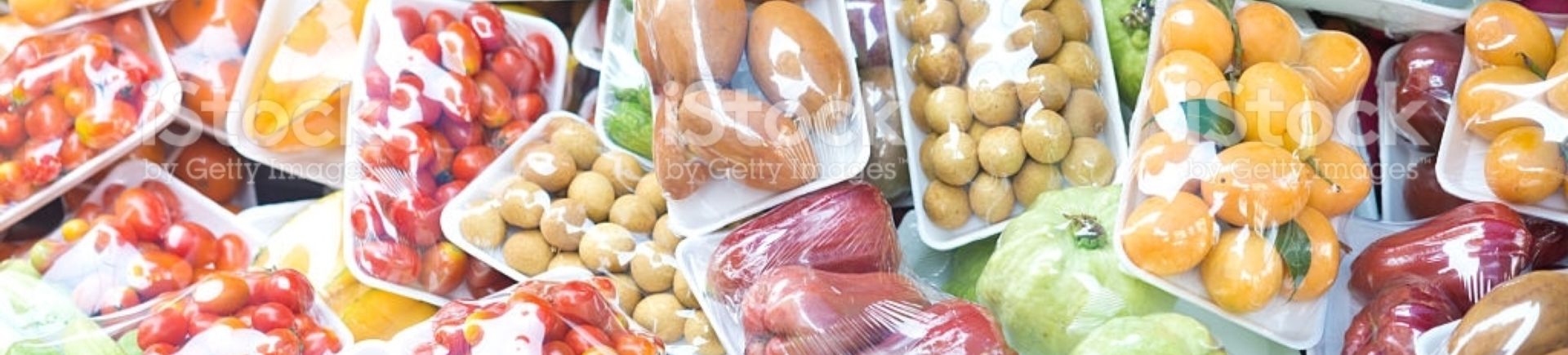

It also features visual properties such as glossiness, clarity, and printability. Flexible film enables brands to present their product in an attractive way. Certain formulations of shrink film are suitable for packaging frozen foods and meats, as they impose barriers to reduce fog or moisture-vapor transmission.

2. Flexible Packaging combines Versatility

Flexible Packaging is versatile, as it offers various options in packaging. For instance, we can create a package that sits on a shelf, stands up or hangs from a peg display. It also provides options that durability and resistance to tearing, freshness and food safety, safe distribution and storage, and protection from environmental components like light, temperature, gas, and moisture.

Flexible film extends the shelf life of biodegradable items and is able to conceal the smells of the packaging’s contents. Manufacturers created stand-up pouches by utilizing flexible film that greatly used for food products, particularly those comes with high-liquid contents. These pouches are both versatile and durable, offering protection to the product during transport and storage.

3. Flexible Packaging Film Reduces Production Costs

There is no need to use more materials than required, as flexible film can be customized as per the particular size of the product. It can match to the goods and offer a higher product-to-package ratio, which will minimize the production costs. The strong utilization of flexible packaging films simplifies the packaging systems, eradicating the cost of capping or labeling, for instance.

The cost of applying flexible packaging film, from materials to production expenses, is remarkably lower than that of glass or plastic containers. Flexible packaging is light-weight, making it affordable to distribute domestically and internationally.

As new technologies are easily available all the time, the packaging costs can be minimized by down-gauging or selecting a film with a lower width.

4. Flexible Packaging Film offers Consumer Conveniences and promotes Reusability

Flexible packaging can be developed to include features like spouts, zip locks, and seals that can be resealed after opening. This advantage helps brands to attract more sales, as consumers are increasingly looking for options that offer greater convenience.

5. Flexible Packaging Film is Environment-friendly

It is important to use packaging materials that meet sustainability standards, as sustainability becomes more significant for Consumer Packaged Goods (CPG) businesses of all sizes. One of the greatest advantages of polyethylene and polyolefin films is that they are recyclable. Industry is continuously putting efforts to make a biodegradable, compostable alternative to plastics that last as long, but there are rare options available in the present time. Additionally, polyolefin film is an FDA-approved food-safe material and it does not deliver harmful vapors during the heat-sealing process.

Flexible packaging film uses less energy during manufacturing process and transportation, and it releases smaller quantities of greenhouse gases on its way to market. With its waste-reduction, recyclability and sustainability options, flexible film helps to encourage product appeal for consumers who prefer purchasing from companies and brands that undertake measures to reduce their ecological footprint and environmental impact.

The aforementioned benefits have impelled this packaging option to the forefront of the CPG industry.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.