All around the globe, we observe a strong food packaging trend towards increased post-consumer recycled (PCR) content. Many brand owners committed to increasing PCR content in water and carbonated soft drink segments. These developments have driven demand and prices up for clear post-consumer recycled bottle flakes. The solution to tackle this challenge is to prepare PET tray flakes for the recycling loop!

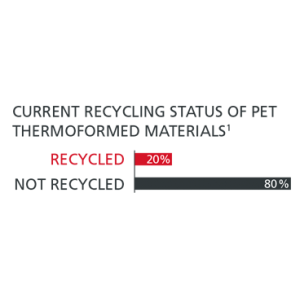

Tray flakes are currently still underutilized. Only around one-fifth of PET thermoformed materials, such as clamshells, cups, trays, or boxes are recovered from the recycling stream in Europe . The situation in the US is very similar according to NAPCOR. “In the North American market post-consumer thermoforms are generally not captured in the PET recycling stream.”, confirms Jeff Cornell, Vice President of Sales at Starlinger-Sahm, Inc. “This is changing with new legislation and improved technologies to sort out this valuable material.”

very similar according to NAPCOR. “In the North American market post-consumer thermoforms are generally not captured in the PET recycling stream.”, confirms Jeff Cornell, Vice President of Sales at Starlinger-Sahm, Inc. “This is changing with new legislation and improved technologies to sort out this valuable material.”

The association Plastic Recyclers Europe estimate, that with more developed reprocessing routes, PET trays can be expected to be collected and recycled at a similar rate to overall plastic packaging. This means, that in the near future, this material will enter the PET recycling loop, and recyclers are now preparing their recycling lines for processing it. Yes, post-consumer PET thermoform is good and usable material, and suitable for upcycling. However, it has lower intrinsic viscosity (IV) and it is amorphous – therefore, the material needs pre-treatment first.

Upcycling PET with deCON iV+

For tray to tray recycling, it is required to keep the intrinsic viscosity of the sheet and the final thermoformed packaging at an optimal level. At the K2019 viscotec has presented the turnkey solution to close the tray recycling loop with deCON iV+. As expected, the response to the solution has been fabulous and it underlines the potential our customers see in tray to tray recycling. “With viscotec’s experience, we are poised to meet the demand for true Tray to Tray circular economy requirements with the deCONiv+: offering crystallization, super cleaning decontamination and iv increase all in one compact unit.”, emphasizes Cornell.

North American and European customers invest in deCON iV

North American and European customers invest in deCON iV

Customers in Europe and the US have purchased the new decontamination dryer. Clients from the US, Great Britain, Poland, Japan, Germany and Italy, are convinced by its functions for the PET thermoform application. The deCONiV+ is designed for the production of dry, iV increased, crystallized, de-dusted post-consumer flakes. The unit processes thermoform flakes, bottle flakes, or in-house skeleton waste and is installed directly in front of a production extruder.

Recovering the iV loss during extrusion

Thanks to the increase of intrinsic viscosity in the deCON iV+ in every recycling cycle, the iV losses are recovered and quality is kept at an optimal level.

- Decontamination of PCR materials exceeding EFSA and FDA standards

- iV increase dedicated for tray recycling

- Excellent de-dusting

- Drying below 50 ppm

- First in First out (FIFO)

- Superior color values

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.