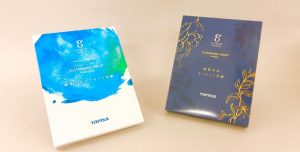

Toyo Ink and ITOCHU to Partner in Building Plastic Recycling Scheme

Toyo Ink SC Holdings Co., Ltd., the parent company of the specialty chemicals manufacturing conglomerate Toyo Ink Group, and ITOCHU Corporation, a leading global trading house, have entered into a cooperative agreement to establish a plastic recycling scheme for the recovery and reuse of multilayer film packaging materials. Specifically, by using their respective technologies and vast business networks, the two firms will develop the materials technology needed to create real circularity of multilayer flexible packaging by making currently unrecyclable multilayer plastic packaging into a recyclable material by 2022.