Trends in the plastic packaging industry

In Asia, rapid urbanisation, growing affluence, and mobility will spur the need for more durable and personalised packaging solutions to meet increasing consumer demand for hygiene, safety and convenience.

The pandemic has also changed consumer needs and buying behaviours, particularly for personal and healthcare products. Global demand has surged for medical supplies, food packaging, and e-commerce packaging. The rise in consumption for such applications shows that plastics has a continuing and vital role in ensuring consumer safety and health, with a need to develop sustainable plastics solutions.

Amid ongoing demand for plastics, calls to relook at global plastic consumption and its implications to the environment continue to grow. Societies worldwide have become more environmentally conscious with the shift in focus to sustainability and circularity.

Growing concern on food waste and safety is also spurring the packaging industry to introduce innovative technologies to develop reusable packaging for food and liquids. The plastics value chain, including brand and retail owners, is responding to customer demand for more sustainable packaging to support the trend to reuse, recycle and reduce, in order to lessen any environmental impact.

Rigid plastics can be a more sustainable solution to replace traditional materials, like glass and metal, for their direct and indirect carbon footprint. For example, a plastic bottle is likely to have a lower carbon footprint due to the lower carbon-intensive production process and transportation.

Innovation meets sustainability

When addressing packaging sustainability, there has been a huge focus on flexible packaging and designing them for recycling to enable a circular economy. Rigid Packaging has often been overlooked in this aspect, though there are also design for recyclability (DFR) guidelines that can be applied to rigid packaging.

Rigid packaging has clear benefits of reusability and ease of recycling. Packaging sustainability extends beyond reusability and recyclability. For instance, environmental benefits are realised through reducing material usage in packaging and ensuring energy efficiency in production by reducing direct manufacturing and transportation footprint.

Aside from sustainability advantages, converters also benefit from improved cost savings and increased productivity in their operations. Taking into account end-to-end production, the right selection of raw material to produce packaging applications can be more cost-efficient and environmentally friendly.

At Borouge, innovation is a key driver of the company’s growth and success. Borouge leverages proprietary technology to develop advanced polymer solutions that provide competitive and sustainable advantages to its customers.

Unique Borstar® and Borstar® Nucleation Technology (BNT)

Generally, the increase of melt flow rate (MFR) will decrease the stiffness (modulus) and toughness (impact) of the polymer. With our Borstar® technology, high MFR polypropylene (PP) can be produced without compromising the material’s mechanical properties.

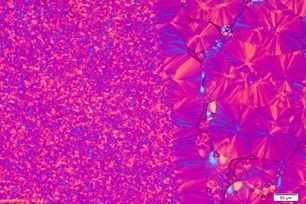

At the same time, BNT is incorporated in our PP during polymerisation, which results in improved stiffness, without negatively affecting impact resistance, enabling downgauging for better material savings. BNT also enables a significant reduction in cycle time due to rapid crystallisation at high temperatures resulting in easier demoulding and improved productivity.

Enhancing Daily Lives

Rigid plastic packaging continues to play a key role in everyday life. The material is versatile, lightweight and highly protective, offering many benefits to brand owners and consumers.

Borouge has a broad portfolio of polypropylene (PP) products serving a diversified market segment in rigid packaging ranging from bottles, caps and closures, thermoforming, thin-wall packaging and speciality houseware. The product offerings in homo polypropylene, random copolymer and impact copolymer enable Borouge to provide solutions for polymer design and property. We continue to develop innovative solutions to support our value chain partners.

Random copolymer RH668MO is a new addition to Borouge’s very comprehensive random copolymer portfolio. Target applications include premium houseware segments like storage boxes and lids, and transparent food containers. For this premium segment, consumers pay for the aesthetics and durability of the products. However, RH668MO goes beyond providing excellent clarity and stiffness-impact. It also brings productivity and possible energy savings, making it a truly differentiated random copolymer designed for high-speed injection moulding lines.

Focus on the future

Rigid packaging will continue to play a significant role in propelling the packaging market, with potential for growth opportunities with the urbanisation of emerging markets. As the world moves towards safeguarding the environment, it is crucial that the packaging industry anticipates future trends, and innovate to position itself to provide solutions in a sustainable way.

“Thoughtful resin design plays a vital role towards achieving sustainability and circularity – the way a resin is designed will provide the pre-requisites for packaging to reduce material usage, energy and transportation footprint and enabling more efficient recyclability at the end of life,” said Aster Teo, Head of Regional Marketing for Packaging, Asia South, Borouge. “With our extensive technical experience in polyolefin design and application development, our team is collaborating with value chain partners to develop solutions to support packaging sustainability.”

Borouge will continue to strengthen our efforts to partner across the value chain and further enhance our industry’s environmental performance by ensuring increasing sustainability in all our processes, products and solutions. We seek to collaborate and create plastic solutions that will enhance daily lives, address future trends, and spur the transformation towards a sustainable packaging economy.

For more information, please contact info@borouge.com

Aster Teois the Head of Regional Marketing for Packaging, Asia South in Borouge since January 2021. Based in Singapore, she is responsible for the overall marketing and growth strategy for the Packaging, Agriculture and Healthcare portfolio in the Southeast Asia, India Subcontinent, Australia and New Zealand regions. Prior to this role, Aster was General Manager for Commercial Excellence, and also held various positions in Sales and Product Management within Borouge.

Before joining Borouge in 2012, Aster worked in different capacities in the Specialty Products and Chemicals industry where she held leadership positions in research and development, business development, and marketing of polymer additives and performance coatings for 18 years.

Sanchita Royis the Application Marketing Manager for the Asia South Packaging Regional Marketing team in Borouge since January 2021. She is responsible for developing, promoting and commercialising innovative and differentiated solutions in flexible and rigid packaging, and developing strategic partnerships across the value chain for Borouge’s packaging business.

Prior to joining Borouge in 2019, Sanchita worked in different capacities in the petrochemical industry, focused on polyolefin business for packaging applications, in areas of customer development, application development, new product launches, new business development, market research, and research and development, for more than 16 years.