A new technology developed by BlakBear in partnership with TPG Rewards lets consumers know how much shelf life is left in every packaged food, even before they purchase it, according to a report in Packaging Digest. This is another technology developed to replace ‘use by’ codes which currently contribute to the massive amount of food wasted each year.

This new ‘cheap and accurate’ sensor for food packaging indicates shelf life in real time via a smartphone app. It has been developed by engineers and scientists at Imperial College London (ICL.). These scientists from ICL have formed a spin-out company, BlakBear, which is starting a partnership with TPG Rewards, a marketing technology company that develops loyalty and promotional programs for some of the largest consumer packaged goods companies in the world.

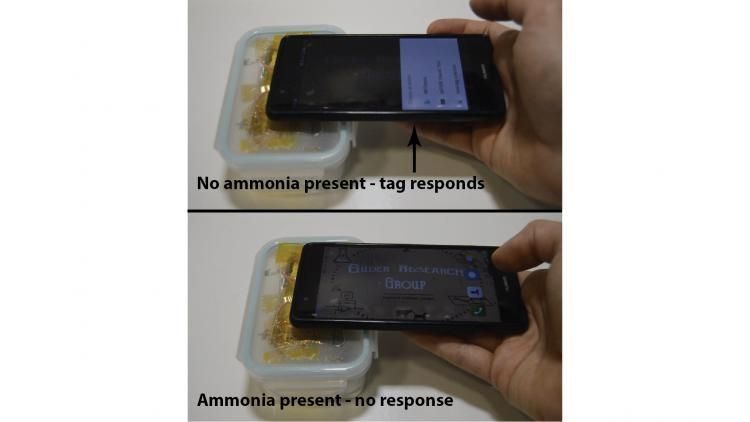

ICL announced last year that it aimed to modernize the current model of pre-printed expiration dates that are based on conservative calculations that assume less than optimum conditions in the supply chain. They claim there is a far better, highly precise method available based on the fact that microbes, which cause food spoilage, emit nitrogenous basic gases such as ammonia. Ammonia levels can be read by a cheap sensor that’s printed on cellulose paper—it costs just two cents each says the developers.

The spin-out company BlakBear, founded by Imperial PhD scientists, “develops new chemistry and electronics for simple chemical sensing, and harnesses new data with AI” that includes leveraging near-field communications (NFC) so that anyone could access the shelf-life data from a smartphone app. In addition it developed the algorithms used by the paper sensors to measure the product freshness and predict the expiry date.

“We can bring it from the lab where it works very well to the industry, and then have producers, retailers and consumers use our technology,” said Giandrin Barandun, BlakBear CTO and author of the study. The company says the technology is appropriate for any fresh food that expires, and has data published for fish and meat. “It informs the consumer how much shelf life is left,” he adds.

As the technology enters the market, BlakBear will keep developing product-specific calibrations that also factor in the package volume, for a single-serving unit versus a multipack, according to BlakBear CEO Max Grell. While that will require additional research. “We’re poised for trials in the United States, Asia, the UK and the rest of Europe,” he says.

TPG are developing the associated app and consumer engagement platform based on a popular NFC-based platform “It’s this platform that is being integrated into the sensors,” explains TPG’s John Galinos. “The platform provides a digital connection between the brand and the consumer at exactly the moment the consumer is about to complete their purchase. The consumer desire to know the product freshness date now can become a conduit for a brand to dialog directly with the consumer.”

The sensor technology and marketing platforms are ready to go, Galinos says. “We would need 12-16 weeks to deploy a program after we have received input from a client as to the type of meat, package type, and what marketing functions they would like to deploy, whether coupons or recipes.” When the BlakBear sensor is layered in, then more leadtime is required for shelf-life determinations.

Source : AIPIA News & Packaging Digest

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.