Developed and produced by Crocco from Vicenza, it comes from an all-Italian supply chain, the raw material is bioplastic from Novamont from Novara, and has already been marketed by excellent food producers such as Melinda who chose it for 100% packaging compostable.

It is developed and produced by Crocco from Vicenza , comes from an all-Italian supply chain , the raw material is bioplastic from Novamont from Novara , and has already been marketed by excellent food producers such as Melinda who chose it for packaging 100 % compostable of organic Melinda apples.

It’s called Leaf and it’s the first food film produced by a completely made in Italy supply chain that can be thrown into the wet fraction of household waste, making this plastic packaging an integral part of the circular economy process.

“This is an innovation that significantly changes the impact of this material which is used every day in millions of homes for the preservation of our food – explains the CEO of Crocco, Renato Zelcher -. This new transparent food film is biodegradable , compostable and partially derived from renewable sources . It is evident that these characteristics have been studied in order to reduce the environmental impact compared to other traditional solutions “.

The film is biodegradable and compostable according to the UNI EN 13432 standard, guaranteed by the OK Compost Industrial mark issued by TÜV Austria, and can therefore be disposed of in the organic fraction of domestic waste and therefore enter the process intended for industrial composting, without impacting on other waste treatment chains.

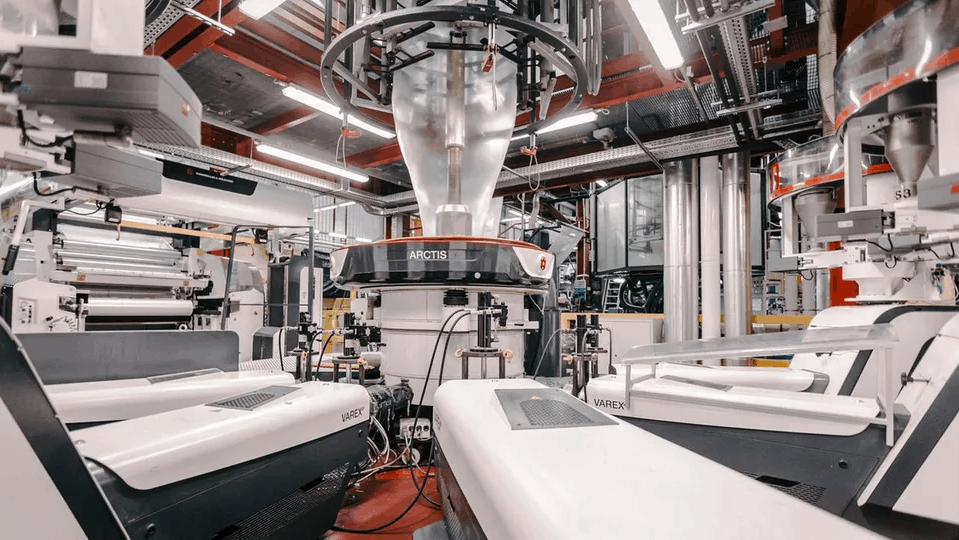

The new compostable film for food can be used both for manual packaging , such as home packaging , in neighborhood shops or in large-scale distribution counters ; but also for automatic packaging , or for large-scale industrial production .

“With regard to the industrial production, also adds the ability to neutralize the, albeit reduced, remaining emissions carbon dioxide film through an eco-design process that Crocco called Greenside :” We are in fact able – explains Zelcher – of measure the Carbon Footprint (i.e. the greenhouse gas emissions throughout its life cycle) of the packaging, possibly redefine its design from the point of view of the thickness and of the material used which may come from recycled or biobased material and, finally, guarantee that the remaining emissions are offset through the purchase of carbon credits, or supporting sustainable projects such as reforestation or production of energy from renewable sources, as required by international agreements “.