FEFCO is proud to announce that the new CO2 footprint for corrugated board is 491 kgCO2e/t showing significant improvement compared to 538 kg CO2e/t in 2018 assessment.

This result reflects the continuous efforts made by the European corrugated industry and its paper suppliers to reduce their impact on the environment. The data for production of paper & board and conversion into corrugated boxes was sourced from the 2021 European Database for Corrugated Board Life Cycle Studies, organised by FEFCO (European Federation of Corrugated Board Manufacturers) and CCB (Cepi ContainerBoard).

The CO2 calculation methodology is based on CEPI’s (Confederation of the European Paper Industries) “Framework for Carbon Footprints for Paper and Board Products, April 2017” and the CITPA (International Confederation of Paper & Board Converters in Europe) “Guidelines for calculating carbon footprints for paper-based packaging, March 2018”. The CEPI and CITPA frameworks have been subject to an independent peer review by ifeu – Institute for Energy and Environmental Research Heidelberg GmbH, Heidelberg, Germany – and have been found to be compatible with the requirements of the “Product Life Cycle Accounting and Reporting Standard” of the Greenhouse Gas Protocol by WRI (World Resources Institute).

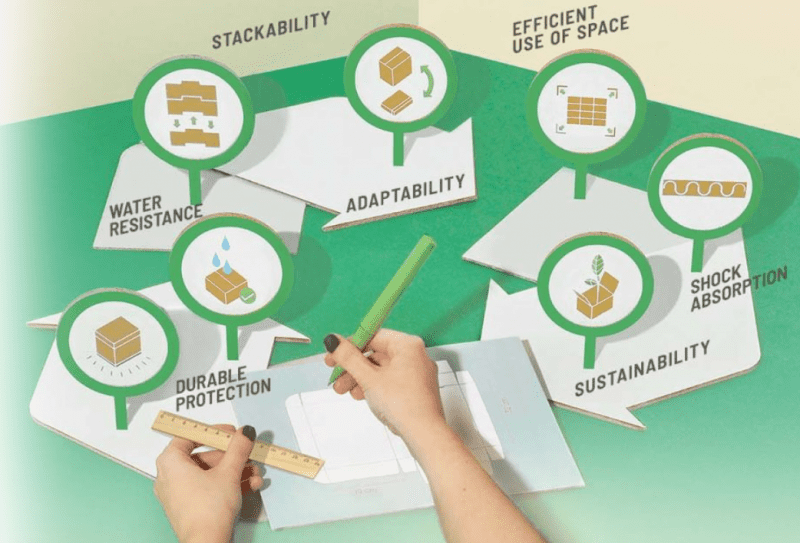

Corrugated board packaging has unique positive attributes. It is based on a renewable raw material and is the most recycled paper and board packaging. Recycled paper and board are used to make new corrugated packaging which on average has 88 % recycling content.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.