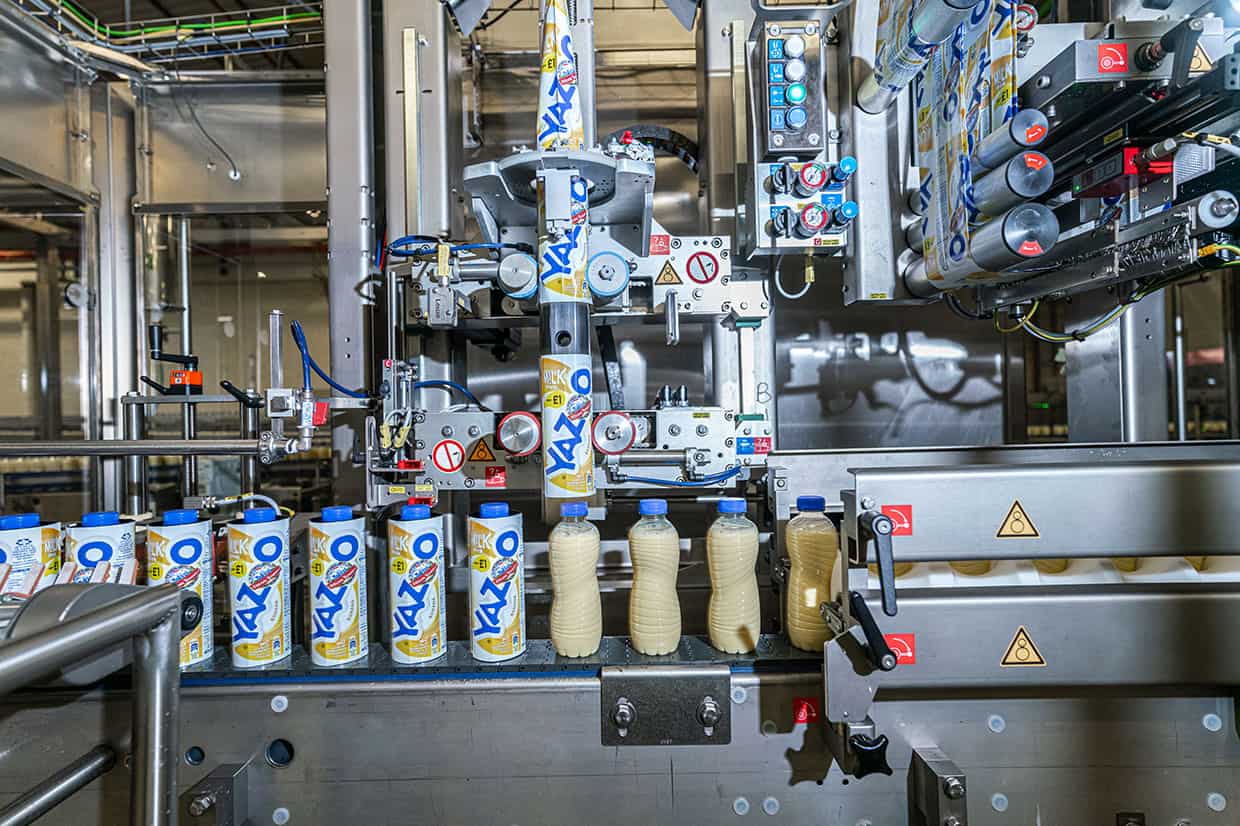

FrieslandCampina has once again chosen Krones dry-aseptic technology and fills its evaporated milk on a Contipure AseptBloc.

“Never change a winning team” may very well be what decision-makers at the dairy cooperative FrieslandCampina thought when it came to upgrading filling capacities for evaporated milk at their facility in the Belgian town of Aalter. And in view of the good experience gained with Line 1, the customer once more opted for a Krones Contipure AseptBloc DN for Line 2.

As one of the world’s biggest dairy cooperatives, FrieslandCampina has always endeavoured to master the balancing act between running a safe and dependable production operation and using state-of-the-art technology. Back in 2014, the company decided to install dry-aseptic technology in its production facility in Aalter (Belgium) for aseptically filling milk and dairy products in PET containers. At the time, it was one of the first Contipure AseptBloc DN systems delivered by Krones, with preform sterilisation, reduced consumption of sterilisation medium and reliable results. Line 1 produces 36,000 containers per hour. FrieslandCampina has now brought an almost identical dry-aseptic line from Krones online, this one rated at 24,000 bottles per hour.

Conscious decision for rPET

FrieslandCampina in Aalter produces longlife milk and milk drinks for the European market. This also includes evaporated milk, which has so far been filled in small glass bottles. But these non-returnable containers no longer met the company’s sustainability criteria since it has pursued a strong sustainability policy along the entire supply chain for years – “from grass to glass” as they would call it themselves.

And therefore FrieslandCampina, as the first dairy company in Belgium decided to use recycled PET here as well – to be more precise containers made of 100% recycled PET (rPET) in order to reduce consumption of virgin PET, and thus new raw material. Another advantage that plastics (no matter whether virgin or recycled) have over glass is their considerably lower weight. The PET containers for evaporated milk, which range from 200 to 500 millilitres in size, weigh between 10 and 16.6 grams. For special markets, FrieslandCampina uses multilayer preforms weighing 12.5 grams.

Additionally, the PET containers are dressed in a sleeve featuring a “zip” over its entire height. This perforated line simplifies recycling because the zip enables consumers to separate the sleeve quite easily from the container before placing each in its appropriate bin.

FrieslandCampina now makes rigorous use of rPET

- The PET containers for evaporated milk weigh between 10 and 16.6 grams.

- Since the use of 100% rPET has proved successful in Line 2, corresponding preforms will in future also be used in Line 1.

Besides their focus on more sustainability, a second major criterion for the purchase of the new line was that filling capacities urgently needed to be upsized since the existing aseptic line with the Contipure AseptBloc DN was running 24/7 – and product demand kept on rising.

One of the world’s biggest dairy cooperatives

FrieslandCampina is owned by around 17,000 dairy farmers from the Netherlands, Belgium and Germany organised in a cooperative. The dairy cooperative runs facilities in 38 different countries and has a payroll totalling about 24,000 people, which ranks it among the world’s biggest dairy cooperatives.

The four business lines are subdivided as follows:

- Food and Beverage

- Specialised Nutrition

- Trading

- Ingredients

The facility in Aalter, located halfway between Bruges and Ghent, is the biggest of FrieslandCampina’s three production sites in Belgium. It is the European hub for longlife milk and milk drinks in cardboard and PET for brands like Campina, Joyvalle, Cécémel, Fristi and Nutroma. In Aalter, a total of eleven cartoning lines are running, three lines for white HDPE containers, three lines for small 7.5-gram portion packs and now two aseptic PET lines from Krones are all up and running. The production location in Lummen is known for its cream specialities under the Debic brand. The plant in Bornem specializes in longlife dairy drinks.

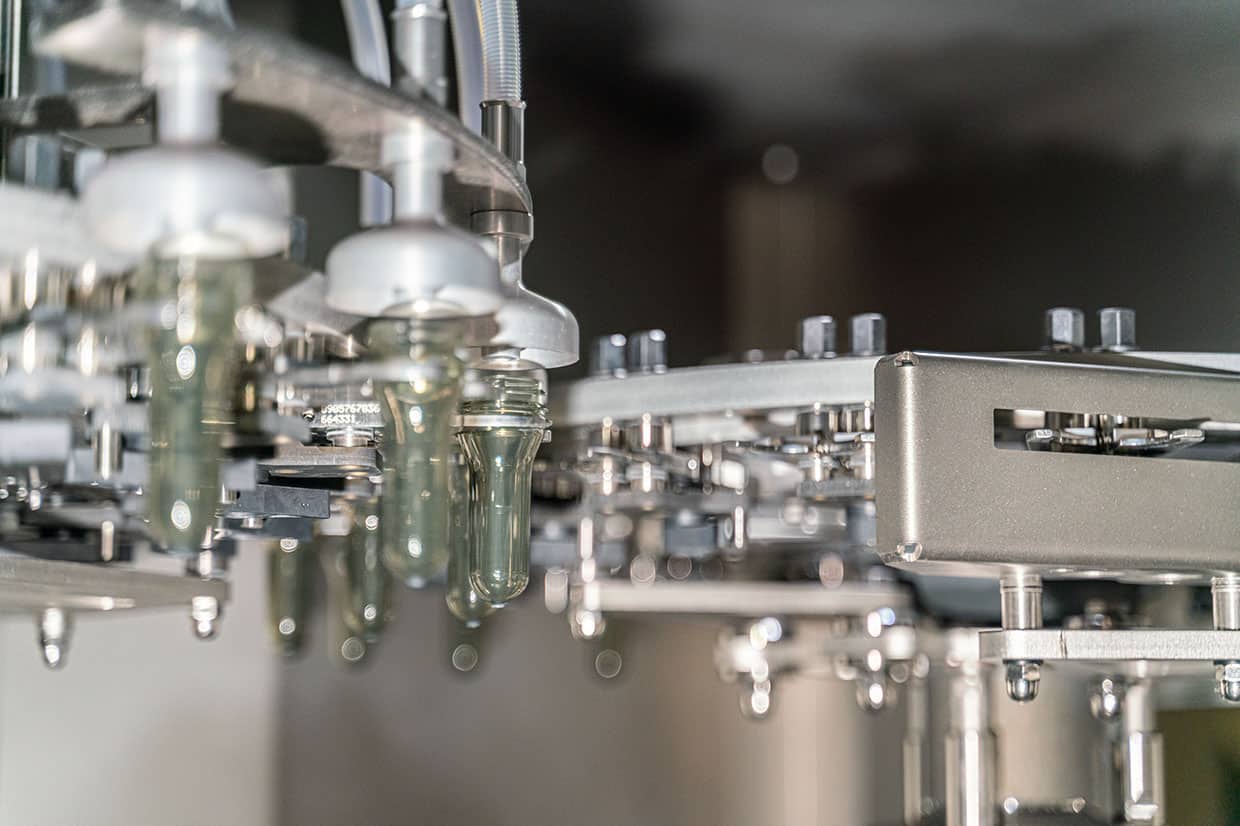

100 per cent sterility

Brecht Deleu had already assisted in putting in place the first aseptic line from Krones in 2014 and was also one of FrieslandCampina’s project managers for the second line. This time he became actively involved in the layout work. In his view, the fact that Krones had meanwhile implemented some essential improvements was an advantage tipping the scales in the company’s favour. “The most important result for us is that the line’s microbiological safety was increased even more. We checked 60,000 bottles, and none of them was unsterile. You can’t get any better than that,” he says.

The most important result for us is that the line’s microbiological safety was increased even more. We checked 60,000 bottles, and none of them was unsterile. You can’t get any better than that.

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.