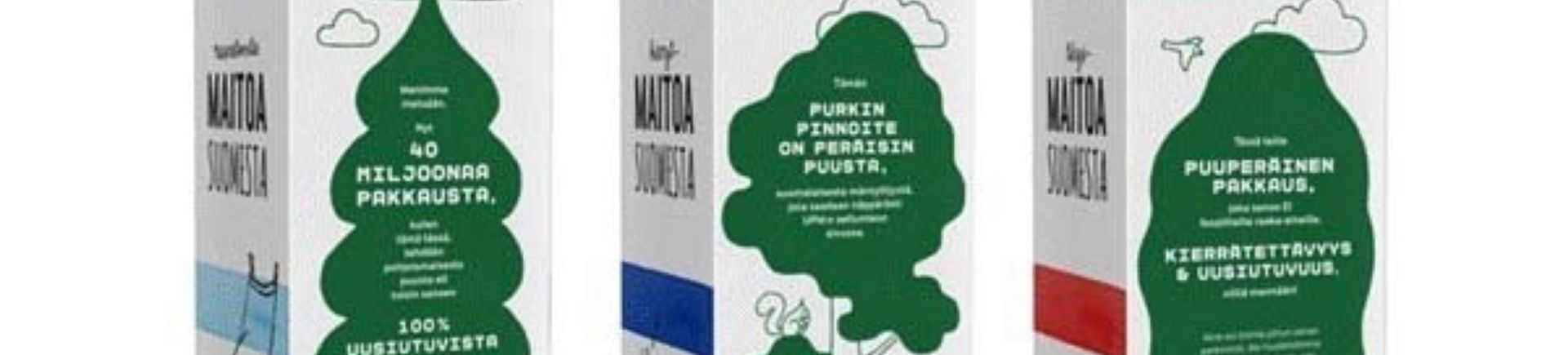

Arla wants to provide consumers with new opportunities for more responsible choices. This year, Arla will be the first in Finland to use renewable wood-based bioplastics, which is a Finnish innovation based on tall oil-based raw materials, in gray-grained cardboard packaging for milk, yoghurts and food products.

As a result of the reform, more than 40 million Arla’s packaging will become more environmentally friendly in 2019, according to consumers’ wishes.

The bioplastics are well suited for the packaging of dairy products, as they have the same technical characteristics as conventional plastic carton packaging. New packaging can be placed in the same way as before.

– In the case of a liquid product such as milk, thin plastic film is needed inside the carton for product safety and durability. In our new packaging, the plastic source is now more responsible as it is made of wood-based raw material, says Arna Brand & Category Manager Sanna Heikfolk .

Wood-based bioplastics reduce the carbon footprint

In the raw material for new plastic cans, UPM’s Lappeenranta biorefinery utilizes tall oil produced as a star in the pulp production process. Packaging is made by Elopak, and is co-operated by the chemical company Dow. Utilizing wood-based bioplastics in Arla’s roofing deck reduces the need for fossil plastics by 180,000 kilos per year and reduces the carbon footprint of about a fifth.

Bringing environmentally-friendly packaging to the food industry and consumers has been a common goal of Arla, Elopak and UPM. Arla and Elopak have been cooperating in this field since 2014 and we wanted to take the packaging development a step further.

– In traditional milk cartons, the carton is usually about 85%. We wanted to offer 100% wood packaging, where plastic is also wood-based, says Juha Oksanen , CEO of Elopak .

Finnish innovation travel from wood to table

As a result of Arla’s packaging reform, UPM’s fine wood-based innovation, UPM BioVerno-naphtha, can now be utilized in the bioplastics of cardboard packaging. UPM’s innovation has the Key Flag symbol of Finnish origin.

– We are very pleased to be a pioneer with Arla, with whom we can further reduce the carbon footprint of liquid board packaging with our renewable raw material – up to the end consumer. Also, using wood-based raw materials, we do not compete with raw materials for food production, because tall oil is a star in pulp production, says Sari Mannonen , President of UPM Biofuels .

Finding more responsible packaging solutions is an ongoing development for Arla. In addition to brick roof packaging, Arla is also renewing 150 grams of Nature + yoghurt packaging by replacing plastic goblets and lids in cartons. Thus, the consumer can put the new packaging completely into the carton collection.

Source: Arla Oy

Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry. Our services include an online content platform to deliver news, insights and case studies; organising conferences seminars and customised training; Providing Bespoke Project Consulting, Market Research and Intelligence.