Cold-Chain biopharmaceutical packaging is fast emerging as a high-technology field, especially in the light of the Covid 19 pandemic.

Krosslinker is an advanced thermal insulation material startup based in Singapore, incorporated in May 2019. KrossLinker has developed superior insulation material to protect temperature-sensitive shipments.

Their first product serves the cold-chain biopharma packaging industry with high-performance thermal insulation material, protect temperature-sensitive pharmaceuticals, precious biologics and vaccines throughout their shipping journey.

In an exclusive interview with Dr R Rangaprasad from Packaging 360, Dr.Gayathri Natarajan, Co-founder & CEO at Krosslinker shares deep insights, into this fascnating technology & many different facets of their innovation. Dr.Gayathri Natarajan holds a Ph.D. Degree in Chemical Engineering from NUS, Singapore.

Dr Rangaprasad: Before we dive into specifics, we would be keen to know how the startup journey has been for you at Krosslinker and what have been the primary drivers for venturing into a startup focussed on solving challenges of cold chain bio- pharmaceutical packaging?

Dr. Gayathri Natarajan: Krosslinker is an advanced thermal insulation material startup based in Singapore, incorporated in May 2019. Our startup was founded by a team of 3 passionate ambitious scientist co-founders (Dr Gayathri Natarajan, Dr Elmira Soghrati and Dr Mahesh Nathan) with several years of combined experience in chemical Engineering, material chemistry and manufacturing & commercialization of advanced materials. We have developed a proprietary process of formulating and fabricating of advanced material called aerogel for challenging thermal insulation applications. Krosslinker’s journey till now has been very fast paced and deeply impactful. We have created a strong culture of experimenting and constant learning.

We started focusing on this cold-chain biopharmaceutical packaging (CCBP) way before Covid pandemic. It is not just Covid vaccine, millions of biopharma products such as blood, clinical trial samples, human organs and precious drugs must be maintained at specific cold temperatures to preserve their efficacy during shipping. Over US$ 300B worth of temperature-sensitive biopharma products are being shipped every year. The complexities of bioproduct portfolios with specific temperature environments, stricter regulations, growing number of shipments (governed by the move from chemical to biological drugs, jump in clinical trials, personalized therapies), extended geographical coverage arising from globalization of speciality pharma commercialization and the necessity for timely delivery renders insulated packaging an essential component in the ecosystem. However, ineffective insulation during the shipping journey results in a US$35B annual loss (product write offs, shipping loss, replacement cost) to the industry because of temperature breaches. There is a real dearth of high-performance insulation material that goes into making these temperatures controlled passive packaging for shippers. Over 90% of the volume of shipments are still done through traditional insulation material (XPS, PU and EPS) and they suffer from the risk of temperature excursions because of poor insulation performance. Further, production and use of single use Styrofoam and polyurethane foam packages pose an environmental threat. Additionally, polyurethane fume exposure during manufacturing and application is a serious health hazard (due to toxic isocyanate compounds).

These are the prime drivers for us to introduce Krosslinker aerogel material to this vertical first. Krosslinker would be the first company to bring aerogels to CCBP vertical.

Dr Rangaprasad: How is the technology developed by you at Krosslinker differentiated from existing ones & what are the industry segments you are targeting?

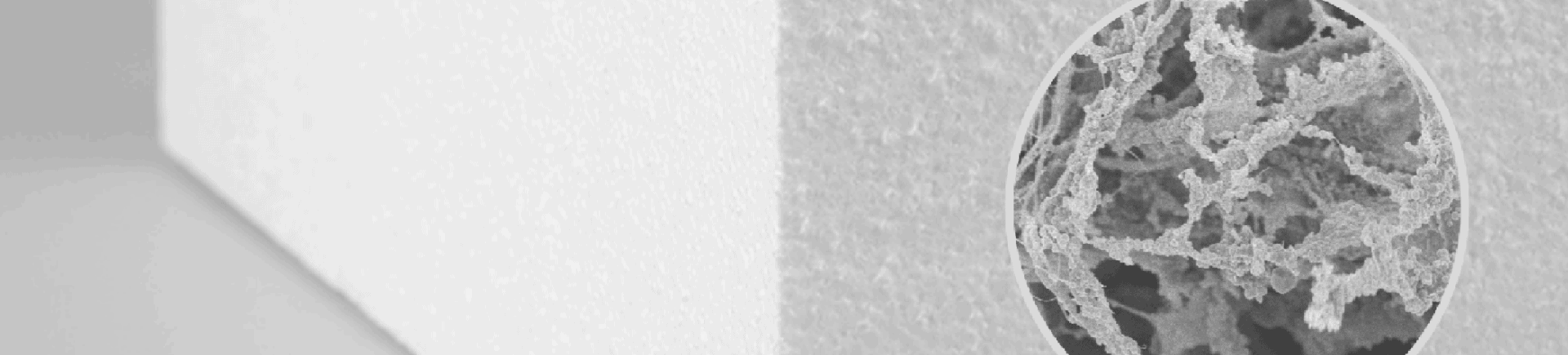

Dr. Gayathri Natarajan: Krosslinker’s aerogel fabrication process addresses the challenges of traditional aerogel manufacturing processes to produce silica aerogel insulation material with proprietary, first-of-its-kind platform technology for fabrication. Despite aerogels being the best insulation material, aerogel manufacturers have been unsuccessful in penetrating this market due to four main challenges: Energy intensive, expensive and slower production process driving up the selling price, thickness limitation (difficulty in fabricating sheets >10 mm with the traditional fabrication methods), dusty formulation (potential contamination threat for bio-pharma) and unavailability of board-type robust aerogel products (current commercial silica aerogels products are available only as powders, granules and flexible blankets). Our technology addresses all these major roadblocks in the product line and has the biggest advantage in terms of ultra-low dust, thickness independent manufacturing process and at least 50% lower production cost (3x faster production time than the current traditional methods, with lowest energy consumption and reduced carbon footprint)

Besides CCBP which is our first vertical, we are also targeting other applications that require cold-insulation such as active reefer truck/container and refrigeration. We will also be soon opening up our manufacturing platform for collaboration and co-development with industry players for applications in other verticals such as construction, high-temperature industrial insulation and electric vehicle battery insulation (for weather and thermal runaway protection). Through this collaborative platform approach, we will get closer to our aim of making this premium material affordable and accessible across all mainstream insulation markets.

Dr Rangaprasad: How did your educational qualification & research work align with the goals & aspirations of Krosslinker?

Dr. Gayathri Natarajan: At Krosslinker, I head the business development and fund-raising efforts. I have seen our technology grow from the ideation stage, all the way through Minimum viable product, several iterative versions of improvement, up to where it is today at the pre-commercialization phase. We are gearing up for pilot trials with potential customers starting from next month. My technical background in chemical engineering has helped me immensely to unleash the potential of this disruptive aerogel production technology, communicate the advantages of our aerogel product to potential customers, identify new verticals/applications for collaborative development and accelerate the path to commercialization.

I have two co-founders, Dr Elmira Soghrati and Dr Mahesh Nathan. Dr Elmira (CTO) is a technical expert with 6 years of experience in product development, material chemistry and design of advanced material. She has a PhD in Chemical Engineering from National University of Singapore. Dr Mahesh Sachithanadam (Director, Innovations and Engineering) is a leading expert in insulation technology with 8 years of experience in engineering, manufacturing and commercializing high-performance insulation material. He is one of the few people in the world who can build the process for producing aerogel insulation material. He has a PhD in aerogel domain with several journal publications, patents, and a book on Silica Aerogel Composites.

Dr Rangaprasad: What are main technical & commercial challenges you come across?

Dr. Gayathri Natarajan: As a team, we have always thought about the risks involved in our technology and tried to address, mitigate and find solutions to the risks. In our technology roadmap, we tie these risks to milestones. I think we have addressed most of the technology risks. One of the risks which we are not able to evaluate now are:

– Risks associated with engineering scale up. This is common with any scale up activities. But this should not be a big problem, as our team puts a great emphasis on de-risking the technology at every level as we leverage on the capacity. Further, we have already established quite a good network and working relationship with vendors and engineering companies.

As with any startup, the pace at which we grow especially at the early stages would be dependent on the investments from venture capital and financial support from industry partners. With the current restrictions and travel ban due to Covid, we are also expecting challenges in hiring foreign talents.

Dr Rangaprasad: How could your technology be useful in the present pandemic situation especially with respect to performance of your products in cold chain & temperature control?

Dr. Gayathri Natarajan: Krosslinker’s aerogel have been tested at a very low operating temperature range, all the way up to -196 C. Our aerogels can be useful for storing and transporting vaccines, patient samples and other drugs at different cold temperature ranges such -80 C, -20 C, 2 – 8 C. Aerogel packages can be used in combination with different coolants such as dry ice and phase change material. Aerogels offer the best thermal insulation, directly translating to reduced risk of temperature breaches during shipping.

-Unlike the traditional foam based insulated packages, the insulation performance of aerogel arises from the material property itself making it ideal for reusability and long-term storage. Multiple use of aerogel-based packaging not only reducing the shipping cost/box cost per use but also significantly limiting the environmental footprint of biopharma shipments. Further, no toxic chemicals or raw materials in the production process making it green and eco-friendly.

– Higher payload capacity with thinner and light-weight insulation will reduce the shipping costs significantly.

Dr Rangaprasad: How does the roadmap for Krosslinker look from here on?

Dr. Gayathri Natarajan: We have completed product development for CCBP. We will be commencing pilot trials with major specialized insulated packaging companies from January. As the first entrant, we will be setting a benchmark for aerogels for this application. Partnerships with packaging companies will help us scale-up faster. Our pilot scale production will commence in mid-2021. We will move to manufacturing-scale production in 2022.

We have also developed customized aerogel formulations using our versatile fabrication platform to yield specific properties (such as water resistant, fire-resistant, high-temperature insulation) for other applications. Following successful market adoption by CCBP customers, we will expand to other verticals such as construction, high-temperature industrial and automotive and EV battery insulation applications. We look forward to broader adoption of aerogel technology via collaboration and partnerships with different industry players for aerogel discovery, prototyping, co-development and commercialization.

Dr. R. Rangaprasad, is currently Business Head, Packaging 360, a Mumbai based knowledge service provider vertical under Catalyzing New Technology (CNT) Expositions & Services LLP. Packaging 360 is a comprehensive knowledge sharing ecosystem for the Indian packaging industry (www.packaging360.in).

Dr. R. Rangaprasad is a chemical technologist by training having earned his Ph.D. (Tech) degree from UDCT (now ICT) in 1992.